Conversion efficiency improved in thermoelectric materials

Researchers from the University of Wollongong (UOW) have overcome a major challenge of thermoelectric materials, improving the materials’ conversion efficiency by more than 60%. Their breakthrough has been published in the journal Advanced Energy Materials.

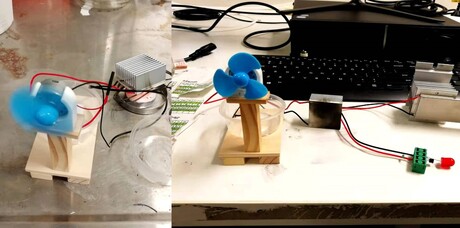

Bismuth telluride-based materials (Bi2Te3, Sb2Te3 and their alloys) are the most successful commercially available thermoelectric materials, with current and future applications falling into two categories: converting electricity into heat, and vice versa. The former is useful for low-maintenance, solid-state refrigeration (heat pumps) with no moving parts, no noise and no vibration, while the latter enables power generation from a wide range of heat sources — including powering micro-devices using ambient or body temperature.

Heat ‘harvesting’ takes advantage of the free, plentiful heat sources provided by body heat, automobiles, everyday living and industrial processes. Without the need for batteries or a power supply, thermoelectric materials could be used to power intelligent sensors in remote, inaccessible locations. But an ongoing challenge of thermoelectric materials is the balance of electrical and thermal properties: in most cases, an improvement in a material’s electrical properties (higher electrical conductivity) means a worsening of thermal properties (higher thermal conductivity), and vice versa.

“The key is to decouple thermal transport and electrical transport,” said PhD student Guangsai Yang, lead author of the new study.

As part of a three-year project at UOW’s Institute of Superconductivity and Electronic Materials (ISEM), researchers found a way to decouple and simultaneously improve both thermal and electronic properties. The team added a small amount of amorphous nano-boron particles to bismuth telluride-based thermoelectric materials, using nano-defect engineering and structural design.

Amorphous nano-boron particles were introduced using the spark plasma sintering (SPS) method. As explained by Professor Xiaolin Wang, corresponding author on the study: “This reduces the thermal conductivity of the material, and at the same time increases its electron transmission.

“The secret of thermoelectric materials engineering is manipulating the phonon and electron transport,” Prof Wang added.

Because electrons both carry heat and conduct electricity, material engineering based on electron transport alone is prone to the perennial trade-off between thermal and electrical properties. Phonons, on the other hand, only carry heat. Therefore, blocking phonon transport reduces thermal conductivity induced by lattice vibrations, without affecting electronic properties.

“The key to improving thermoelectric efficiency is to minimise the heat flow via phonon blocking, and maximise electron flow via [electron transmitting],” Yang said. “This is the origin of the record-high thermoelectric efficiency in our materials.”

The result is record-high conversion efficiency of 11.3%, which is 60% better than commercially available materials prepared by the zone melting method. As well as being the most successful commercially available thermoelectric materials, bismuth telluride-based materials are also typical topological insulators.

“The decoupling of electronic (electron-based) and thermal (phonon-based) transport will be a game changer in this industry,” Prof Wang said.

Please follow us and share on Twitter and Facebook. You can also subscribe for FREE to our weekly newsletter and bimonthly magazine.

Novel design enhances battery-based seawater desalination

Engineers have developed a solution to eliminate fluid flow "dead zones" in electrodes...

How halide perovskites could transform light-powered energy tech

Researchers from the University of Missouri have explored how a material called halide...

Battery-like computer memory keeps working in extreme heat

The material transports oxygen ions rather than electrons, creating heat-resistant voltages for...