Novel design enhances battery-based seawater desalination

Engineers have found a way to eliminate the fluid flow “dead zones” that plague the types of electrodes used for battery-based seawater desalination. The new technique uses a physics-based tapered flow channel design within electrodes that moves fluids quickly and efficiently, potentially requiring less energy than reverse-osmosis techniques currently require.

Technical hurdles have prevented the wide-scale implementation of desalination technology. The most-used method, reverse osmosis, pushes water through a membrane that filters out the salt and is costly and energy-intensive. By contrast, the battery method uses electricity to draw charged salt ions out of the water. Still, it also requires energy to help push the water through electrodes that contain tiny, non-uniform pore spaces.

“Traditional electrodes still require energy to pump fluids through because they do not contain any inherently structured flow channels,” said University of Illinois Urbana-Champaign mechanical science and engineering professor Kyle Smith, who led the study. “However, by creating channels within the electrodes, the technique could require less energy to push the water through and eventually become more efficient than what is commonly used in the reverse-osmosis process.”

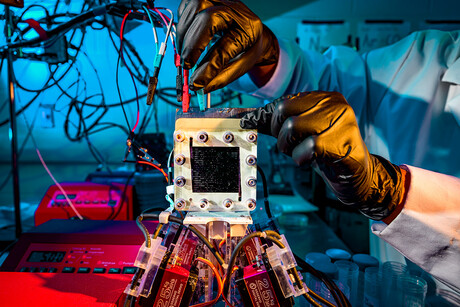

Smith’s battery-based desalination technique builds from years of modelling and experiments by his research group at Illinois, culminating in a recent study demonstrating the first use of electrodes containing tiny microchannels called interdigitated flow fields.

The group’s new study also incorporates IDFFs in electrodes, but this time the channel shape is tapered, not straight. Using electrodes with tapered channels improved fluid flow — or permeability — two to three times over straight channels. The findings are published in the journal Electrochimica Acta.

“Our initial work on straight channels in electrodes led us to discover dead zones within the electrodes where we saw pressure drops and non-uniform flow distribution,” said Illinois graduate student Habib Rahman. “To overcome this challenge, we created a library of 28 different straight channels to experiment with and understand conductance and flow variation, and eventually implemented this channel-tapering technique.”

While performing the experiments, Smith and Rahman said they faced some manufacturing challenges, particularly with the time it takes to mill the channels into the electrodes, which would be problematic in any scaled-up production scenario. However, Smith said they are confident this challenge can be overcome.

“Beyond its impact toward electrochemical desalination, our channel-tapering theory and associated design principles can be applied directly to any other electrochemical device that uses flowing fluids, including those for energy storage conversion and environmental sustainability like fuel cells, electrolysis cells, flow batteries, carbon capture devices and lithium recovery devices,” said Smith. “Unlike prior channel-tapering strategies that used impromptu designs, our approach here provides physics-based design guidelines to create uniform flow and minimise pressure drops simultaneously.”

Molecular Velcro coating boosts solar cell efficiency

Researchers have developed a new coating layer that enhances the durability and efficiency of...

Predictive AI model enhances solid-state battery design

ECU researchers are working on ways to make solid-state batteries more reliable with the help of...

Boosting performance of aqueous zinc–iodine batteries

Engineers from the University of Adelaide have enhanced aqueous zinc–iodine batteries using...