Silicon anodes stabilised in Li-ion batteries

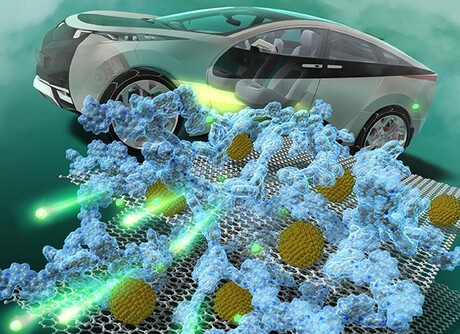

With the prevalence of electric vehicles and electronic devices set to increase, efforts have been directed towards improving the performance and longevity of lithium-ion (Li-ion) batteries. Now researchers from the Japan Advanced Institute of Science and Technology (JAIST) have shown that adding a polymer composite binder to a battery’s silicon anode can significantly improve structural stability, resulting in more powerful, longer-lasting batteries.

Any typical Li-ion battery today consists of a positive electrode (cathode) made up of a lithium-containing compound, a negative electrode (anode) made up of graphite, and electrolyte — the layer in between the electrodes through which ions flow. When a battery is charged, lithium ions flow from the cathode to the anode, where they are stored. During the discharge process, the lithium is ionised and moves back to the cathode.

Recently, there has been a growing interest in using silicon as the anode material because it is more abundant, and therefore cheap, and has a higher theoretical discharge capacity than graphite. However, repeated charging and discharging causes the silicon particles to expand and rupture. This results in the formation of a thick solid-electrolyte interface (SEI) between the electrolyte and the anode, which hinders the movement of lithium ions between the electrodes.

To improve the performance of silicon anodes in Li-ion batteries, JAIST researchers have developed a binder for the silicon particles, which can improve their stability and maintain a thin SEI layer. In contrast to a thick SEI layer, a thin one is beneficial because it prevents the anode and electrolyte from spontaneously reacting with each other.

The binder is a polymer composite consisting of an n-type conducting polymer poly(bisiminoacenaphthenequinone) (P-BIAN) and a carboxylate-containing polymer poly(acrylic acid) (PAA), each linked to the other via hydrogen bonds. The composite polymer structure holds the silicon particles together like a net and prevents them from rupturing. The hydrogen bonds between the two polymers permit the structure to self-repair, as the polymers can reattach themselves if they break away at any point. Moreover, the n-doping ability of P-BIAN improves the conductivity of the anode and maintains a thin SEI by limiting the electrolytic decomposition of the electrolyte on the anode.

To test the binder, the researchers constructed an anodic half-cell consisting of silicon nanoparticles with graphite (Si/C), the binder (P-BIAN/PAA) and an acetylene black (AB) conductive additive. The Si/C/(P-BIAN/PAA)/AB anode was put through a repeated charge–discharge cycle. The P-BIAN/PAA binder was observed to stabilise the silicon anode and maintain a specific discharge capacity of 2100 mAh g-1 for over 600 cycles. In contrast, the capacity of the bare silicon-carbon anode dropped to 600 mAh g-1 within 90 cycles.

After the test, the researchers disassembled the anode and examined the material for any cracks that might have resulted from silicon rupture. A spectroscopic and microscopic examination after 400 cycles revealed a smooth structure with only a few microcracks, indicating that the addition of the binder was able to improve the structural integrity of the electrode and maintain a uniform SEI.

The results of the study, published in the journal ACS Applied Energy Materials, thus demonstrate that the addition of the binder can improve the characteristics of the silicon anode, making it a practically feasible and environmentally friendly alternative to graphite.

Please follow us and share on Twitter and Facebook. You can also subscribe for FREE to our weekly newsletter and bimonthly magazine.

Computational model enhances battery safety

Researchers have developed a new computational model that offers insights into one of the key...

Novel method to extend lifecycle of Li-ion batteries

Researchers have uncovered a hidden surface degradation mechanism in the cathodes of lithium-ion...

Sensor could help prevent Li-ion battery fires

Researchers have developed new technology to detect dangerous gas leaks in lithium-ion batteries,...