Micro-supercapacitors built directly on a chip

A new method of carbon thin-film deposition is said to allow microchips and their energy sources to be collocated on a silicon wafer.

Researchers at Drexel and Paul Sabatier University initially created the carbide-derived carbon film material for micro-supercapacitors in 2010. Since then, their goal has been to show that it’s possible to physically couple the processing centre of an electronic device — the microchip — with its energy source.

The latest findings confirm a belief held by the group since the materials were first fabricated — that these films are versatile enough to be seamlessly integrated into the systems that power silicon-based microchips that run devices from your laptop to your smart watch.

The challenges that the group faced in the development of the material were questions about its compatibility, its mechanical stability and its durability for use on flexible substrates. With these answered, it opens up a myriad of possibilities for carbon films to work their way into silicon chips — including building microscale batteries on a chip.

“The place where most people will eventually notice the impact of this development is in the size of their personal electronic devices, their smartphones, fitbits89 and watches,” said Gogotsi, Distinguished University and Trustee Chair Professor in the Department of Materials Science Engineering who directs the A.J. Drexel Nanomaterials Institute in Drexel’s College of Engineering. “Even more importantly, on-chip energy storage is needed to create the Internet of Things — the network of all kinds of physical objects ranging from vehicles and buildings to our clothes embedded with electronics, sensors and network connectivity, which enables these objects to collect and exchange data. This work is an important step toward that future,” said Gogotsi.

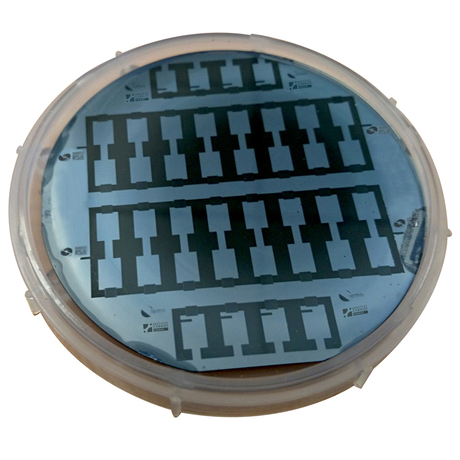

The researchers’ method for depositing carbon onto a silicon wafer is consistent with microchip fabrication procedures currently in use, thus easing the challenges of integration of energy storage devices into electronic device architecture. As part of the research, the group showed how it could deposit the carbon films on silicon wafers in a variety of shapes and configurations to create dozens of supercapacitors on a single silicon wafer.

Supercapacitors have been desirable devices to use in microelectronics because they can store a great deal of energy for their size, they can be charged and discharged their energy extremely quickly and their lifespan is nearly limitless. With this discovery, the path is clear for microchip manufacturers to take a big step forward in the way they design their products.

Beyond the energy storage applications, these carbon films offer good prospects for the development of elastic coatings with a low coefficient of friction that can be used in lubricant-free sliding parts, such as dynamic seals. They may also be used in production of membranes for gas filtration, water desalination or purification, because their pore size is in the range of single molecules. The carbon films produced by this method are quite versatile and may find applications in many areas.

Computational model enhances battery safety

Researchers have developed a new computational model that offers insights into one of the key...

Novel method to extend lifecycle of Li-ion batteries

Researchers have uncovered a hidden surface degradation mechanism in the cathodes of lithium-ion...

Sensor could help prevent Li-ion battery fires

Researchers have developed new technology to detect dangerous gas leaks in lithium-ion batteries,...