Creating electrocatalysts for zinc-air batteries

Researchers at The University of Sydney have solved what is said to be one of the biggest stumbling blocks preventing zinc-air batteries from overtaking conventional lithium-ion batteries as the power source of choice in electronic devices.

Zinc-air batteries are batteries powered by zinc metal and oxygen from the air. Due to the global abundance of zinc metal, these batteries are much cheaper to produce than lithium-ion batteries. They can also store more energy (theoretically five times more than that of lithium-ion batteries) and are much safer and more environmentally friendly.

While zinc-air batteries are currently used as an energy source in hearing aids and some film cameras and railway signal devices, their widespread use has been hindered by the fact that, up until now, recharging them has proved difficult. This is due to the lack of electrocatalysts that successfully reduce and generate oxygen during the discharging and charging of a battery.

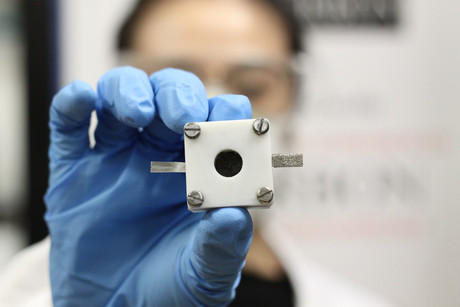

Now, chemical engineering researchers have outlined a three-stage method to overcome this problem. According to Professor Yuan Chen, lead author of the paper published in Advanced Materials, the method can be used to create bifunctional oxygen electrocatalysts for building rechargeable zinc-air batteries from scratch.

“Up until now, rechargeable zinc-air batteries have been made with expensive precious metal catalysts, such as platinum and iridium oxide,” he said. “In contrast, our method produces a family of new high-performance and low-cost catalysts.”

These new catalysts are produced through the simultaneous control of the composition, size and crystallinity of metal oxides of earth-abundant elements such as iron, cobalt and nickel. They can then be applied to build rechargeable zinc-air batteries.

Dr Li Wei, a co-author on the paper, said trials of zinc-air batteries developed with the new catalysts had demonstrated excellent rechargeability — including less than a 10% battery efficacy drop over 60 discharging/charging cycles of 120 hours.

“We are solving fundamental technological challenges to realise more sustainable metal-air batteries for our society,” Professor Chen said.

Computational model enhances battery safety

Researchers have developed a new computational model that offers insights into one of the key...

Novel method to extend lifecycle of Li-ion batteries

Researchers have uncovered a hidden surface degradation mechanism in the cathodes of lithium-ion...

Sensor could help prevent Li-ion battery fires

Researchers have developed new technology to detect dangerous gas leaks in lithium-ion batteries,...