Design democratisation

Supporting a burgeoning spirit of ‘democratisation’ in micro-manufacturing, 3D printing is quickly growing in popularity across Australia’s active community of makers.

When used in combination with low-cost hardware products such as Arduino Due and Raspberry Pi, and desktop, model-based design tools MATLAB and Simulink, the possibilities are endless and, most importantly, achievable.

To celebrate the new capability for direct deployment of MATLAB and Simulink to low-cost boards such as Raspberry Pi and Arduino, MathWorks kicked off a project earlier this year that included everything necessary for makers to simulate and build an autonomous, 3D-printed Mars Rover.

In using Simulink’s graphical interface, the project demystified numerical simulation, showing how the design process can be more intuitive and accessible than ever before. Here, the state machine guided the discovery of waypoints based on what the simulated Mars Rover camera found in the scene. Implementing this sort of computational model in a text-based approach would be much less direct, however. Without simulation, each debugging iteration would require compilation and download, and therefore be much more time-consuming.

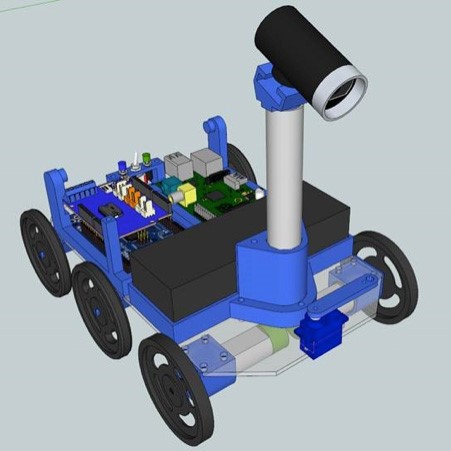

The 3D-printed Mars Rover

Built around a simple 3D-printed chassis, the Rover Mathworks developed was based on two very common and low-cost embedded systems: Arduino Due and Raspberry Pi. The ARM Cortex-M-powered Arduino Due and its peripherals allow for future sensor payloads, while the 700 MHz CPU and 512 MB of RAM on Raspberry Pi offer the power of embedded Linux and its community of support. The robot’s current incarnation is limited to a sensor payload of just a webcam and wheel encoders, but this is enough for basic navigation and mapping.

At a competition organised by MathWorks at the Paris Maker Faire, almost 300 people used the platform to make the Rover, each getting access to the full design environment and simulation models, and submitting their improvements to qualify for the final event. Twelve teams qualified for the event, with one team coming from as far as India. Each team was provided a robot by MathWorks, which it used the entire day to find and navigate its Martian waypoints faster than the other teams. The Martian waypoints were green dots in a red environment seen by the camera and analysed by a computer-vision algorithm that detects their locations relative to the robot. A control algorithm then uses these distance and bearing measurements for the robot’s motors to travel from one dot to another. Since then, 3D printers around the world have been replicating the design, and the maker spirit of democracy rolls on.

The algorithms designed in the simulation phase were deployed to the Rover’s two processors, at which point the environment allows graphical monitoring and debugging. There’s no need for IDEs, compilers, JTAG emulators, mutexes, communication middleware or driver stacks. The mantra here is algorithms and hardware, a philosophy that can allow makers to re-use the project an infinite number of times. You can innovate, put your own twist on it, add sensors or intelligence, build a swarm and share back to the repository.

To industry veterans using model-based design to create highly complex control systems, they may be surprised to see how their secret design tool is now the backbone of a simplified, low-cost tool for the rest of the world.

Visit MATLAB Central for documentation and MATLAB and Simulink files to power a robot competition/workshop designed around a Mars Rover theme.

Encryption: the key to embedded security

Designers of embedded systems must keep up with the latest cyber threats and develop long-lasting...

A replacement for traditional motors could enhance next-gen robots

Researchers at Stanford have designed a spring-assisted actuator — a device that can...

A leap towards computers with light-speed capabilities

Scientists have created a reprogrammable light-based processor that could help enable successful...