3D printing of light-activated hydrogel actuators

An international team of researchers has embedded gold nanorods in hydrogels that can be processed through 3D printing to create structures that contract when exposed to light — and expand again when the light is removed. Because this expansion and contraction can be performed repeatedly, the 3D-printed structures can serve as remotely controlled actuators.

“We knew that you could 3D print hydrogels that would contract when heated,” said Joe Tracy, co-corresponding author of a paper on the work and a professor of materials science and engineering at North Carolina State University. “And we knew that you could incorporate gold nanorods into hydrogels that would make them photoresponsive, meaning that they would contract in a reversible manner when exposed to light.

“We wanted to find a way to incorporate gold nanorods into hydrogels that would allow us to 3D print photoresponsive structures.”

Hydrogels are polymer networks that contain water. Examples include everything from contact lenses to the absorbent material used in diapers. And, technically, the researchers didn’t print a hydrogel with the 3D printer. Instead, they printed a solution that contains gold nanorods and all of the ingredients needed to create a hydrogel.

“And when this printed solution is exposed to light, the polymers in the solution form a cross-linked molecular structure,” said Julian Thiele, co-corresponding author of the paper and chair of organic chemistry at Otto von Guericke University Magdeburg. “This turns the solution into a hydrogel, with the trapped gold nanorods distributed throughout the material.”

Because the pre-hydrogel solution coming out of the 3D printer has a very low viscosity, you can’t print the solution onto a regular substrate — or you’d have a puddle instead of a 3D structure.

To solve this problem, the researchers printed the solution into a translucent slurry of gelatine microparticles in water. The printer nozzle is able to penetrate the gelatine slurry and print the solution into the desired shape. Because the gelatine is translucent, light can penetrate the matrix, converting the solution into a solid hydrogel. Once this is done, the entire thing is placed in warm water, melting away the gelatine and leaving behind the 3D hydrogel structure.

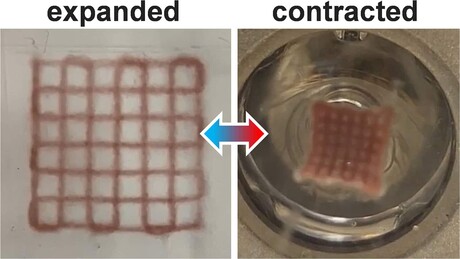

When these hydrogel structures are exposed to light, the embedded gold nanorods convert that light into heat. This causes the polymers in the hydrogel to contract, pushing water out of the hydrogel and shrinking the structure. However, when the light is removed, the polymers cool down and begin absorbing water again, which expands the hydrogel structure to its original dimensions.

“A lot of work has been done on hydrogels that contract when exposed to heat,” said Melanie Ghelardini, first author of the paper and a former PhD student at NC State. “We’ve now demonstrated that you can do the same thing when the hydrogel is exposed to light, while also having the capability to 3D print this material. That means applications that previously required direct application of heat could now be triggered remotely with illumination.”

“Instead of applying conventional mould casting, 3D printing of hydrogel structures offers nearly unlimited freedom in design,” Thiele said. “And it allows for pre-programming distinct motion during light-triggered contraction and expansion of our photoresponsive material.”

The research findings have been published in the journal Polymers.

Smarter quantum computers with dual-code error correction

Researchers have developed a method with which a quantum computer can switch back and forth...

Harnessing electromagnetic waves to improve wireless communication

Researchers have enhanced the frequency conversion of terahertz waves in graphene-based...

Neuromorphic semiconductor chip corrects errors autonomously

Researchers have developed a computing chip that can learn, correct errors and process AI tasks.