How to use a digital multimeter — Part 2

Digital multimeters (DMMs) can be useful for a variety of measurements. This article is Part 2 of a two-part series that explains how to use a digital multimeter. This article discusses cover resistance measurements, continuity and diode testing.

Resistance measurements

Resistance measurements are commonly used to measure resistors or other components such as sensors or speakers.

Resistance measuring works by applying a known DC voltage over an unknown resistance in series with a small internal resistance. It measures the test voltage, then it calculates the unknown resistance. Because of this, test the device only when it isn't powered, otherwise there is already voltage in the circuit and you can get incorrect readings. Also, keep in mind that a component should be measured before it is inserted into the circuit, otherwise you are measuring the resistance of everything connected to the component instead of just the component by itself.

One of the nice things about resistance is that it is non-directional, meaning if you switch the probes the reading is still the same. The symbol for a resistance measurement is Ω, which represents the resistance unit of measure. Be sure to select the correct range and mode for your application. If the display reads OL, this means the reading is over the limit or greater than the meter can measure in that range. As discussed earlier, using the null offset can improve your measurement readings.

Additional measurements

Many DMMs offer two additional measurement functions: continuity testing and diode testing.

Continuity testing

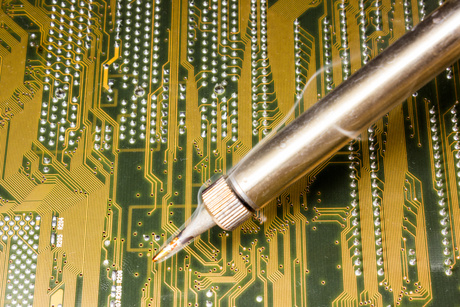

Continuity testing helps you identify when two points are electrically connected. This can be helpful when troubleshooting wire breaks, printed circuit board (PCB) traces or solder joints. When testing for continuity, it is essential to monitor exactly where the probes are touching. As such, most DMMs emit a sound when they detect a closed circuit, so you don't have to look up from your probes. As such, the symbol for continuity looks like a sound wave.

Continuity testing works just like a resistance measurement; as such, it is essential that your device not be powered when you are testing. It can also be helpful to make sure everything is connected first by brushing the test tips together to verify the beep. If you don't hear a sound, then check that the probes are firmly connected, your DMM has sufficient battery life and that you are in the correct mode. You should also look in your user manual to determine the level of resistance required to trigger the sound as it varies from model to model.

If you are testing a circuit that has a large capacitor, you may hear a quick beep and then silence. This is because the voltage the DMM is applying to the circuit is charging up the capacitor and, during that time, the DMM thinks it is a closed circuit when it isn't really.

Diode testing

Diode testing displays the forward voltage drop of the diode in volts. The symbol, not surprisingly, is the diode symbol.

The DMM forces a small current through the diode and measures the voltage drop between the two test leads. When measuring a diode, you want the positive probe on the anode side and the negative on the cathode side. The voltage reading typically is about 0.7 V for silicon but can range from 0.5 to 0.9 V and still be a working diode. Germanium diodes are typically around 0.3 V.

Next, switch probes so the negative is on the anode side and the positive is on the cathode side. If the diode is working properly, the multimeter should show that there is an open circuit indicated by OL.

If a diode is defective, it can defect to be either a short or an open diode. If the diode has failed to open, the DMM shows OL in both the forward and reverse bias because the current flowing through is zero and is an equivalent to an open circuit. If the diode is shorted, the DMM indicates 0 V as there is no voltage drop across the diode.

Noise rejection parameters

It is always important to consider noise when taking a measurement. There are two additional parameters you should be familiar with to better understand your instrument and the associated noise of the measurement.

The normal-mode rejection ration (NMRR) describes the DMM's ability to reject noise that appears between the two input terminals or, in other words, the noise mixed in with the measured signal. Most of this noise is a line frequency and its harmonics. NMRR, which is often used to indicate the capability of the instrument to reject a power line noise of 50 or 60 Hz, is valid only at the specified frequency and is useful when making DC measurements. Normal-mode noise can also be reduced through the use of shielding or filtering.

The common-mode rejection ratio (CMRR) describes the DMM's ability to reject noise that is common to both input terminals, such as from a noisy environment. Common-mode noise is usually less severe than normal-mode noise.

NMRR and CMRR are typically specified at 50 Hz and 60 Hz, and CMRR is often specified at a DC value as well. Typical values are greater than 80 dB and 120 dB, respectively.

Summary

- The number of display digits on a DMM is not related to the resolution but can help determine the number of significant values that can be displayed and read.

- For most applications, it can be said the higher the impedance, the more accurate the voltage measurement.

- Higher crest factors indicate sharper peaks and make it more difficult to get an accurate AC measurement.

- Null offset can be used to eliminate errors caused by connections and wires when making a DC voltage or resistance measurement.

- Auto zero is used to compensate for internal instrument offsets.

- Current measurements require you to break the circuit in order to insert the DMM into the circuit loop.

- Accidentally measuring voltage while in the current mode can cause a fuse to blow.

- Resistance measurements and continuity testing should be taken when the circuit does not have power.

- The normal-mode rejection ratio (NMRR) describes the DMM's ability to reject noise that appears between the two input terminals.

- The common-mode rejection ratio (CMRR) describes the DMM's ability to reject noise that is common to both input terminals, such as from a noisy environment.

To read Part 1 of this two-part series, click here.

Turning RFID tags into scalable passive sensors

Researchers from UC San Diego have used low-cost RFID tags to develop analog passive sensors that...

Smart buoy tech live streams data 24/7 from sea floor

A Perth-based company has developed the Nodestream protocol, a bespoke solution that uses...

Engineers discover a new way to control atomic nuclei as “qubits”

Using lasers, researchers can directly control a property of nuclei called spin, that can encode...