Waterproof pressure sensors for wearable electronics

Flexible and waterproof sensors that could unlock new applications for wearable electronics have been developed by scientists at Soongsil University. Published in the journal Science and Technology of Advanced Materials, the team’s study shows how the pressure sensor can control a phone to take photos and play music — even when the sensor is fully immersed in water.

“Flexible electronics will usher in a whole new world of wearable technologies to monitor our health and lifestyles,” said materials scientist Jooyong Kim, who led the research. “But until now, many of these applications have been held back because the pressure sensors they rely on could not handle being exposed to water. We have changed that.”

The sensor converts tiny movements caused by change in pressure and electrical resistance into electronic signals. Like many similar flexible electronic devices, the design of the circuit was hand-drawn onto a conducting material with a marker-pen, which acts to shield the circuitry when the rest of the material is etched away. This is cheaper than traditional methods.

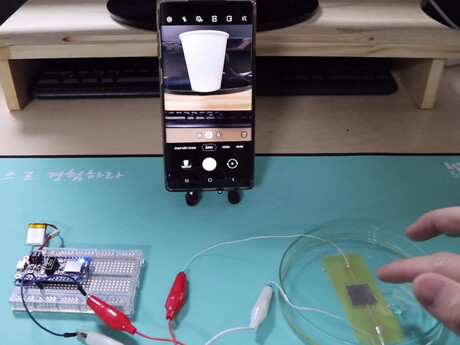

The researchers then mounted the fingerprint-sized circuit onto a blend of wet tissue paper and carbon nanotubes, which works to detect changes in pressure. They then covered the layered sensor device with a strip of tape, to make it waterproof.

The device can track both the magnitude and location of pressure applied to it. Using machine learning technology to process the signals, the researchers found the sensors could feel and report applied pressures in the lab with up to 94% accuracy. By connecting the sensor to a Wi-Fi network, the researchers could press it underwater to control phone functions, including double-touch, triple-touch, short-touch and long-touch patterns.

The technology could transform the use of wearable electronics in health care and smart textiles, as well as for specific applications including scuba diving equipment. To demonstrate the power of the technology, the researchers incorporated one of the sensors into a flexible face mask. Sensitive enough to detect the movement of air inside the mask, the sensor could track and report the rate of breathing of a wearer in real time.

“We expect the readily available materials, easy fabrication techniques and machine learning algorithms we have demonstrated in this journal article will bring significant contributions to the development of hand-drawn sensors in the future,” Kim said.

Please follow us and share on Twitter and Facebook. You can also subscribe for FREE to our weekly newsletter and bimonthly magazine.

AI-powered wearable turns gestures into robot commands

A new wearable system uses stretchable electronics and artificial intelligence to interpret human...

Graphene-based solar cells power temperature sensors

Researchers have demonstrated the ultra-low-power temperature sensors powered by graphene-based...

3D-printed diamond device powers medical implants

Researchers from RMIT University have developed a 3D-printed diamond–titanium device that...