Researchers create wearable medical patch with nanotech, AI

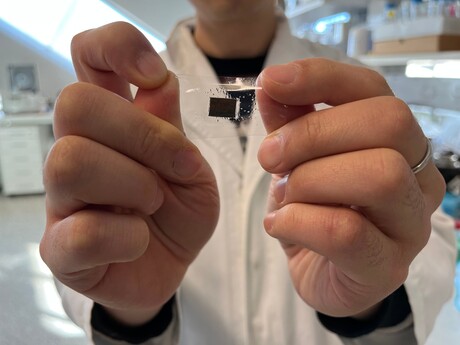

Researchers at Monash University have developed an ultra-thin skin patch with nanotechnology that can monitor 11 health signals. Researchers from the Faculty of Engineering and Faculty of Information Technology combined nanotechnology and artificial intelligence to bring machines one step closer to communicating with the human body. Using specialised algorithms, personalised Artificial Intelligence (AI) technology can disentangle multiple body signals, understand them and make a decision on what to do next.

Published in Nature Nanotechnology, the research could change how remote health care is delivered, and the future of personal alarms and communications devices. Worn on the neck, lead researcher Professor Wenlong Cheng said the wearable patch has three layers, measuring speech, neck movement and touch. It also measures breathing and heart rates. “Emerging soft electronics have the potential to serve as second-skin-like wearable patches for monitoring human health vitals, designing perception robotics and bridging interactions between natural and artificial intelligence,” Cheng said.

Associate Professor Zongyuan Ge is part of the Monash team to have developed a frequency/amplitude-based neural network called Deep Hybrid-Spectro that can automatically monitor multiple biometrics from a single signal. “As people all sound and act differently, the next step is to program and personalise the sensors using even more sophisticated algorithms so they can be tailored to individuals,” Ge said.

The sensor is made from laminated cracked platinum film, vertically aligned gold nanowires and a percolated gold nanowire film. Neck skin is among the most sensitive skin on the body and connects up to five physiological activities associated with the human throat: speech, heartbeats, breathing, touch and neck movement.

The research was carried out at the Monash Nanobionics lab and in part at the Melbourne Centre for Nanofabrication (MCN) in the Victorian Node of the Australian National Fabrication Facility (ANFF) and the Monash Centre for Electron Microscopy.

AI-powered wearable turns gestures into robot commands

A new wearable system uses stretchable electronics and artificial intelligence to interpret human...

Graphene-based solar cells power temperature sensors

Researchers have demonstrated the ultra-low-power temperature sensors powered by graphene-based...

3D-printed diamond device powers medical implants

Researchers from RMIT University have developed a 3D-printed diamond–titanium device that...