Innovative robotic tech empowers pipe inspection

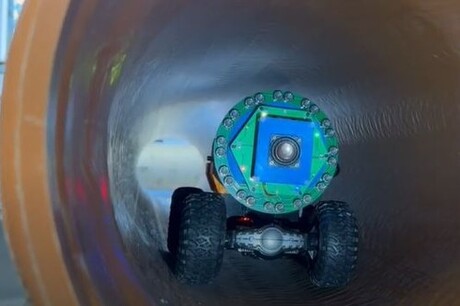

Researchers from the University of Bristol, led by Professor Bruce Drinkwater and Professor Anthony Croxford, have demonstrated an inspection design method and procedure by which mobile robots can inspect large pipe structures. The method was used to carry out the successful inspection of multiple defects on a three-metre-long steel pipe using guided acoustic wave sensors.

The new approach was used to review a long steel pipe with multiple defects, including circular holes of different sizes, a crack-like defect and pits, through a designed inspection path to achieve 100% detection coverage for a defined reference defect. In the study, published in NDT and E International, the researchers showed how they examined large plate-like structures using a network of independent robots, each carrying sensors capable of sending and receiving guided acoustic waves, working in pulse-echo mode.

This approach minimises communication between robots, requires no synchronisation and raises the possibility of on-board processing to lower data transfer costs and reduce overall inspection expenses. The inspection was divided into a defect detection and a defect localisation state. Lead author Dr Jie Zhang said there are many robotic systems with integrated ultrasound sensors used for the automated inspection of pipelines from inside, allowing pipeline operators to perform required inspections without stopping the flow of product in the pipeline. However, available systems struggle to cope with varying pipe cross-sections or network complexity, leading to pipeline disruption during inspection. This makes them suitable for specific inspections of high-value assets, such as oil and gas pipelines, but not generally applicable.

“As the cost of mobile robots has reduced over recent years, it is increasingly possible to deploy multiple robots for a large area inspection. We take the existence of small inspection robots as [a] starting point, and explore how they can be used for generic monitoring of a structure. This requires inspection strategies, methodologies and assessment procedures that can be integrated with the mobile robots for accurate defect detection and localisation that is low cost and efficient. We investigate this problem by considering a network of robots, each with a single omnidirectional guided acoustic wave transducer. This configuration is considered as it is arguably the simplest, with good potential for integration in a low cost platform,” Zhang said.

The methods used are generally applicable to other related scenarios and allow the impact of any detection or localisation method decisions to be quickly quantified. The methods can also be used across other materials, pipe geometries, noise levels or guided wave modes, allowing the full range of sensor performance parameters, defect sizes and types and operating modalities to be explored.

The researchers will now collaborate with industries to advance current prototypes for actual pipe inspections.

Novel biosensor increases element extraction efficiency

Biologists have developed a novel biosensor that can detect rare earth elements and could be...

Making sensors more sustainable with a greener power source

A new project aims to eliminate the reliance of sensors on disposable batteries by testing the...

Fission chips — using vinegar for sensor processing

Researchers have developed a new way to produce ultraviolet (UV) light sensors, which could lead...