Bionic finger renders 3D images of electronic devices

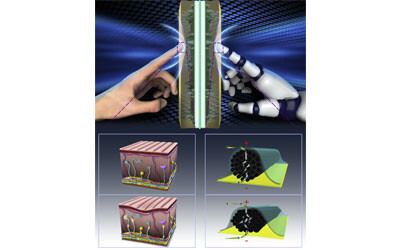

In a study published in the journal Cell Reports Physical Science, researchers have presented a bionic finger that can create 3D maps of the internal shapes and textures of complex objects by touching their exterior surface. Senior author Jianyi Luo, a professor at Wuyi University, said the researchers were inspired by human fingers, which have the sensitive tactile perception. “For example, when we touch our own bodies with our fingers, we can sense not only the texture of our skin, but also the outline of the bone beneath it,” Luo said.

Co-author Zhiming Chen, a lecturer at Wuyi University, said the researchers’ bionic finger goes beyond previous artificial sensors that are only capable of recognising and discriminating between external shapes, surface textures and hardness. The bionic finger ‘scans’ an object by moving across it and applying pressure, akin to a constant stream of pokes or prods. With each poke, the carbon fibres compress, and the degree to which they compress provides information about the relative stiffness or softness of the object. Depending on the object’s material, it might also compress when poked by the bionic finger: rigid objects hold their shape, while soft objects will deform when enough pressure is applied. This information, along with the location at which it is recorded, is relayed to a personal computer and displayed onscreen as a 3D map.

The researchers tested the bionic finger’s ability to map out the internal and external features of complex objects made of multiple types of material, such as a rigid ‘letter A’ buried under a layer of soft silicon, as well as more abstractly shaped objects. When the finger was used to scan a small compound object made of three different materials — a rigid internal material, a soft internal material and a soft outer coating — it was able to discriminate between the soft outer coating and the internal hard ridges, and could also tell the difference between the soft outer coating and the soft material that filled the internal grooves.

The researchers also tested the finger’s ability to sense and image simulated human tissue. The tissue consisted of a skeletal component, made of three layers of hard polymer, and a soft silicone ‘muscle’ layer, and was made using 3D printing. The bionic finger was able to reproduce a 3D profile of the tissue’s structure and locate a simulated blood vessel beneath the muscle layer.

The researchers also explored the bionic finger’s ability to diagnose issues in electronic devices without opening them up. By scanning the surface of a defective electronic device with the bionic finger, the researchers could create a map of its internal electrical components and pinpoint the location at which the circuit was disconnected, as well as a mis-drilled hole, without breaking through the encapsulating layer.

“This tactile technology opens up a non-optical way for the nondestructive testing of the human body and flexible electronics. Next, we want to develop the bionic finger’s capacity for omnidirectional detection with different surface materials,” Luo said.

Novel biosensor increases element extraction efficiency

Biologists have developed a novel biosensor that can detect rare earth elements and could be...

Making sensors more sustainable with a greener power source

A new project aims to eliminate the reliance of sensors on disposable batteries by testing the...

Fission chips — using vinegar for sensor processing

Researchers have developed a new way to produce ultraviolet (UV) light sensors, which could lead...