Cellulose nanofibres help protect flexible electronics

Researchers from Osaka University have developed a cellulose nanofibre coating that counters bending damage and retains electrode function underwater. Described in the journal ACS Applied Nanomaterials, the coating is believed to offer unparalleled water resistance for flexible electronic devices.

Most electronic devices aren’t waterproof, though some can be made at least water-resistant by, for example, using special glues to fuse outer components together. Flexible electronics are another story. Their sealant materials must be able to bend, yet with current technology it’s inevitable that eventually such a sealant will crack or separate from the device.

Cellulose nanofibres have been proposed as a potential polymer coating for flexible electronics. These fibres are made from renewable resources and are environmentally friendly. However, they usually absorb water — commonly thought to be a fatal limitation for imparting water resistance.

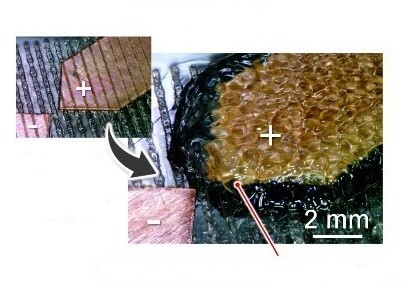

Osaka University researchers developed self-healing cellulose nanofibres that slightly disperse in water and act to protect a copper electrode, enabling the electrode to function for an extended period. The researchers’ flexible circuit protection mechanism retains electrode function underwater and can undergo hundreds of bending cycles.

“In our initial work, an unprotected copper electrode failed after five minutes of dripping water onto it,” said Takaaki Kasuga, lead author on the study. “Remarkably, a cellulose nanofibre coating prevented failure over at least a day of the same water challenge.”

This occurred because cellulose fibres don’t repel water; instead, the polymer coating migrates in the electrode in such a way to prevent formation of conductive metal filaments that cause short circuits. The electrodes even maintained their function after the cellulose coating was scratched to simulate bending damage.

“Our results aren’t attributable to simple ion exchange or nanofibre length,” said senior author Masaya Nogi. “The nanofibres aggregate in water into a protective layer made cohesive by locally acidic conditions and polymer cross-linking.”

A more rigorous test of the polymer coating was its performance after 300 cycles of bending underwater over the course of an hour. A conventional polymer coating usually failed, but the cellulose nanofibres continued to power LEDs. Even an ultrathin polymer coating thickness of only 1.5 µm, and some other polymers, performed similarly to the originally tested set-up.

“You’ll be able to stretch, bend and fold electronics with our coating, and they’ll still retain their water resistance,” Kasuga said. “This is critical for use in applications under extreme conditions where device failure is unacceptable — for example, medical devices used in emergency disaster response.”

Please follow us and share on Twitter and Facebook. You can also subscribe for FREE to our weekly newsletter and bimonthly magazine.

Materials display unique combo of stiffness, thermal insulation

Researchers have engineered materials that are stiff and capable of insulating against heat. This...

Cosmetic ingredient used for battery protection

Researchers have developed a battery electrode protective film using biopolymers sourced from...

Quantum key distribution system achieves high transmission speed

Researchers have developed a quantum key distribution system based on integrated photonics that...