Quantum dot solar cells are non-toxic and defect-tolerant

Researchers at Los Alamos National Laboratory have developed novel quantum dot solar cells that match the efficiency of existing quantum dot-based devices, but without lead or other toxic elements that most solar cells of this type rely on.

Not only did the researchers demonstrate highly efficient devices, they also revealed the mechanism underlying their remarkable defect tolerance. Instead of impeding photovoltaic performance, the defect states in copper indium selenide quantum dots actually assist the photoconversion process. Their breakthrough has been published in the journal Nature Energy.

Quantum dots have already found many uses; in particular, they are very efficient light emitters. They are distinct from other types of light-emitting materials, as their colour is not fixed and can be easily tuned by adjusting the quantum dot size. This property has been utilised in displays and televisions, and soon will help make more efficient, colour-adjustable light bulbs.

The unique physics of nanosized semiconductor crystals prepared by colloidal synthesis has had scientists fascinated for decades. Due to their extremely small sizes — a few nanometres across — the properties of the nanocrystals can be manipulated at the most fundamental quantum-mechanical level; hence, they are called ‘quantum dots’.

Size-tuneable properties of quantum dots can also help efficiently capture sunlight, which is of great use in solar energy conversion. The efficiencies of modern quantum-dot solar cells are rapidly approaching those of traditional thin-film photovoltaics; however, in most cases they contain highly toxic heavy metals such as lead and cadmium, which limits their practical utility.

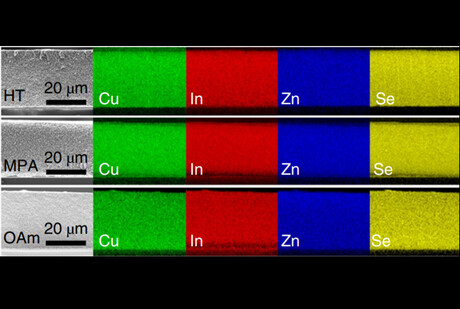

Los Alamos researchers have now described high-efficiency quantum dot solar cells that are free of any toxic elements. The team used a reaction of copper, indium and selenium, with the addition of zinc to make zinc-doped quantum dots. The dots were incorporated into voids of a highly porous titania film that served as a charge-collecting electrode.

Incident solar photons were absorbed by the quantum dots, which resulted in the release of tightly bound electrons into a high-mobility conduction band. These electrons were then transferred to the titania electrode, which ultimately produced a photocurrent.

“We were pleasantly surprised by the results of the measurements of our devices,” said Los Alamos physicist Victor Klimov, lead author of the study. “Due to their very complex composition (four elements are combined in the same nanosized particle), these dots are prone to defects. Despite these imperfections, they showed nearly perfect performance in our solar cells — per each 100 absorbed photons we detected 85 photogenerated electrons, implying that the photon-to-electron conversion efficiency was 85%.”

The high photoconversion efficiencies, combined with the remarkable defect tolerance and toxic-element-free composition, makes these quantum dots promising materials for implementing inexpensive, readily scalable and potentially disposable solar cells.

Please follow us and share on Twitter and Facebook. You can also subscribe for FREE to our weekly newsletter and bimonthly magazine.

Molecular Velcro coating boosts solar cell efficiency

Researchers have developed a new coating layer that enhances the durability and efficiency of...

Predictive AI model enhances solid-state battery design

ECU researchers are working on ways to make solid-state batteries more reliable with the help of...

Boosting performance of aqueous zinc–iodine batteries

Engineers from the University of Adelaide have enhanced aqueous zinc–iodine batteries using...