Long-lasting lithium–sulfur battery developed

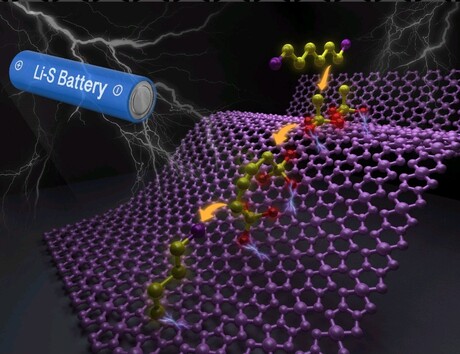

Researchers at South Korea’s Gwangju Institute of Science and Technology (GIST) have improved the performance and durability of lithium–sulfur batteries, which are attracting attention as a potential next-generation energy storage technology. The research team introduced cobalt oxalate as an electrochemical catalyst at the anode interface of a lithium–sulfur battery and succeeded in identifying the electrochemical catalyst reaction during the charging and discharging process.

Theoretically, lithium–sulfur batteries have five times more energy density than conventional lithium-ion batteries, as well as being economical and eco-friendly. They can be used for medium and large energy storage devices such as electric vehicles, as well as portable electronic devices and ultralight and ultrasmall special equipment. However, low life expectancy due to the non-conductive properties of sulfur and the elution of lithium polysulfides generated during the charging and discharging process act as a major obstacle to commercialisation.

Recently, catalyst research has been underway to improve the performance of lithium–sulfur batteries, but to improve the performance more efficiently, high-efficiency conversion of sulfur — which has low production costs and is non-conductive — is needed. There is a lack of research to identify electrochemical reaction mechanisms that enable this transformation.

Led by Professor Jaeyoung Lee, the GIST research team synthesised cobalt oxalate as an electrochemical oxidation/reduction catalyst using a very simple chemical precipitation method to produce gram units and applied it to the positive electrode of a lithium–sulfur battery. The results of their work were published in the journal ChemSusChem.

The cobalt oxalate electrochemical catalyst-based anodes were able to minimise the self-discharge generated by the lithium polysulfide moving inside the cell by absorbing the generated lithium polysulfide on the catalyst and the surface of the positive electrode. In addition, it was confirmed that cell performance continued without performance degradation due to self-discharge, even if the battery was left for about a week, at about 1.5 times the level of conventional lithium–sulfur batteries.

“The research results are most significant in securing capacity improvement and durability of lithium–sulfur batteries, which can implement high energy density at low cost through electrochemical catalyst reactions,” Prof Lee said. “Subsequent research is expected to contribute greatly to the development of next-generation energy storage technologies by gradually improving the durability of lithium–sulfur batteries.”

Please follow us and share on Twitter and Facebook. You can also subscribe for FREE to our weekly newsletter and bimonthly magazine.

Predictive AI model enhances solid-state battery design

ECU researchers are working on ways to make solid-state batteries more reliable with the help of...

Boosting performance of aqueous zinc–iodine batteries

Engineers from the University of Adelaide have enhanced aqueous zinc–iodine batteries using...

Sodium-ion battery breakthrough boosts energy storage

Scientists have discovered that leaving water inside a key material, rather than removing it,...