Ammonium: the secret ingredient for stable perovskite solar cells?

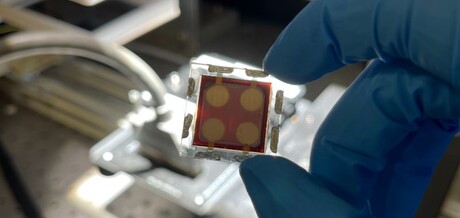

Members of Exciton Science, based at Monash University, have developed a new pathway to creating durable, efficient perovskite photovoltaics at industrial scale. The pathway was demonstrated through the first effective use of lead acetate as a precursor in making formamidinium–caesium perovskite solar cells. Researchers were able to create perovskite solar cells with 21% efficiency, reportedly the best results ever recorded for a device made from a non-halide lead source.

A minor prototype solar panel featuring these cells achieved 18.8% efficiency. The large-area perovskite layer was fabricated in ambient atmosphere and was made via a single-step blade coating, demonstrating its potential viability for industrial-scale manufacturing. The test devices also showed strong thermal stability, continuing to function with no efficiency loss after 3300 hours running at 65°C.

First author Jie Zhao, a PhD student at Monash University, said the researchers used lead acetate in a one-step, spin-coating process to get the perfect, high-quality formamidinium–caesium perovskite thin film. “And because we don’t need an anti-solvent agent, we can do this via large-scale techniques, such as blade coating, which means it’s viable at industrial scale,” Zhao said.

The results were published in Energy & Environmental Science. Corresponding author and Monash University colleague Dr Wenxin Mao said the majority of solar cell research uses lead halides, particularly lead iodide. According to Mao, the lead iodide needs to be 99.99% pure and it is very expensive to synthesise cells using lead iodide. “We’re the first group to make highly stable formamidinium–caesium perovskite solar cells using lead acetate rather than lead iodide. We have provided the entire research community a second way to make high-quality perovskite solar cells,” Mao said.

Thin film solar cells made from perovskites have the potential to disrupt the solar energy sector, due to their low manufacturing cost, flexibility and tunable band gap relative to silicon. However, researchers are struggling to solve reliability issues, and they also need to find a way to create devices at a viable commercial scale. Perovskites are solution processed (made in liquid) using a variety of ingredients. Most approaches use lead halides and require the inclusion of strong polar solvents with high boiling points and antisolvent quenching agents to control the perovskite crystallisation process.

This complicated mechanism can lead to defects in the thin films, which causes the resulting device to lose efficiency; it is also hard to control. The chemical compound lead acetate could be an alternative precursor, because it can create ultra-smooth thin films with fewer defects. Until now, lead acetate had only been used to make methylammonium or caesium-based perovskites, which are relatively unstable and not suitable for real-world applications.

A better candidate for commercial use is found in perovskites made using formamidinium and caesium, due to their superior stability. Previous attempts to synthesise them using lead acetate as the precursor failed. To solve this issue, the researchers examined the underlying molecular mechanisms. Through X-ray diffraction and nuclear magnetic resonance spectroscopy, they identified the need to use ammonium as a volatile cation (positively charged ion) at a critical stage.

“The presence of ammonium served to drive away the residual acetate during annealing, without forming unwanted side products,” said contributing author Dr Sebastian Fürer.

The researchers believe their work on the fundamental chemistry governing precursor behaviour can encourage a greater focus on scalable synthesis and fabrication methods of metal halide perovskite devices.

Wearable generator powers electronics by body movements

Researchers have developed a device that can generate electricity from vibrations or even small...

Ion speed record holds potential for faster battery charging

Scientists have broken a speed record using nanoscience that could lead to new advances in...

CSIRO opens facility to bring flexible solar tech to market

CSIRO has launched its state-of-the-art Printed Photovoltaic Facility in south-east Melbourne, to...