Making batteries work without external pressure

A team of battery researchers led by the University of California San Diego and University of Chicago has developed a new methodology to produce the potentially game-changing thin-film solid-state electrolyte called lithium phosphorus oxynitride (LiPON).

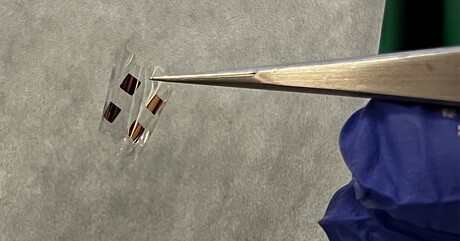

The team went on to implement their freestanding version of LiPON film in functional battery tests and found that it promotes a uniformly dense lithium metal electrochemical deposition under zero external pressure, with the aid of internal compressive stress and a gold seeding layer. This work, performed by a team of battery researchers led by the University of California San Diego and University of Chicago, was published in the journal Nature Nanotechnology.

The research team is led by battery researcher and Professor Ying Shirley Meng, who is affiliated with both the University of Chicago and UC San Diego. The first author is Diyi Cheng, a recently graduated PhD in the Materials Science and Engineering Program at the UC San Diego Jacobs School of Engineering who is continuing his research efforts at Lawrence Berkeley National Laboratory. The team also includes researchers from Lawrence Livermore National Laboratory and UC Berkeley.

LiPON shows strong promise for pairing with a broad range of electrode materials for the lithium battery industry of the future. However, existing methods for producing LiPON have prevented researchers from fully understanding the material. Now, the team found a way to produce this promising solid-state electrolyte in a freestanding form that allows LiPON to be studied more comprehensively. The new approach to making LiPON has also opened the door to using this solid-state electrolyte to enable lithium metal solid-state batteries that could work under minimal external pressure.

The LiPON Challenge

LiPON was originally developed by a group of scientists at Oak Ridge National Laboratory in 1992. Despite continuous research efforts over the last three decades, there remains a substantial lack of thorough understanding of LiPON’s intrinsic properties and its associated interfaces, holding back the promise and advancement of LiPON materials. Several factors leading to this dilemma include:

- LiPON is an amorphous material that gives little structural information by regular diffraction-based techniques.

- LiPON is sensitive to ambient air and electron beams, which further confines the available tools for study.

- Traditional LiPON synthesis is conducted on solid substrates. This approach is inadequate for generating conclusive signals for spectroscopic measurements.

New approach to LiPON production leads to new insights

Given the known challenges to studying LiPON, the team developed a new methodology for producing LiPON film in a freestanding form. The result is a flexible and transparent freestanding LiPON (FS-LiPON) film that is compatible with a broad range of spectroscopic techniques that have greater chances of unravelling the unique properties of LiPON over the diffraction-based techniques. This advance yielded fresh insights, described in the new Nature Nanotechnology paper on LiPON’s interfacial chemistry, thermal properties and mechanical properties. Insights include:

- Solid-state nuclear magnetic resonance measurement uncovered a quantitative view of interface formation between lithium metal and LiPON.

- Differential scanning calorimetry measurements showed a well-defined glass-transition temperature of LiPON around 207 degrees Celsius.

- Nanoindentation measurement gave a Young’s modulus of LiPON around 33 GPa.

Uniformly dense lithium metal deposition under zero external pressure

In addition to gleaning new fundamental insights on LiPON, the research team also implemented the new freestanding version of the solid-state electrolyte in functional battery tests. The team reports that the thin-film FS-LiPON promotes a uniformly dense lithium metal electrochemical deposition under zero external pressure, with the aid of internal compressive stress and a gold seeding layer. This finding gives valuable hints regarding interface engineering in bulk solid-state batteries.

LiPON-based thin film batteries have shown great potential for wearables and other compact electronic devices with a gigantic market. The FS-LiPON film produced in this work described by Diyi Cheng et al. in Nature Nanotechnology enabled in-depth discussions on interfacial chemistry, ion diffusion and interface engineering, which shed light on both the fundamentals and applications of LiPON materials, and could benefit the lithium solid-state battery development in many ways.

A fluid battery that can take any shape

Using electrodes in a fluid form, researchers have developed a battery that can take any shape.

Key factors to consider with fire protection for an EV battery

This article explores some factors for EV battery designers to consider when deciding on...

Researchers claim record PV efficiency for kesterite solar cell

UNSW researchers have reportedly set a new record for a kesterite solar cell, which could be a...