Stretchable fibres can detect touch

Researchers from North Carolina State University (NC State) have developed elastic, touch-sensitive fibres that can interface with electronic devices. Their work has been published in the journal Advanced Functional Materials.

As explained by Michael Dickey, corresponding author on the paper, “Touch is a common way to interact with electronics using keyboards and touch screens. We have created soft and stretchable fibres that can detect touch, as well as strain and twisting.”

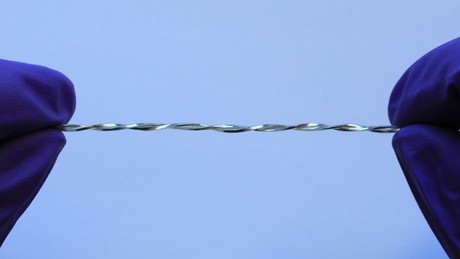

The new fibres are made of tube-like polymer strands, each of which is only a few hundred microns in diameter, which contain a liquid metal alloy: eutectic gallium and indium (EGaIn). Each fibre consists of three strands: one is completely filled with EGaIn, one is two-thirds filled with EGaIn and one is only one-third filled with EGaIn. The slim tubes are then twisted together into a tight spiral.

The touch-responsive fibre works because of capacitance, or the phenomenon in which electric charge is stored between two conductors separated by an insulator. For example, when your finger (a conductor) touches the screen of your smartphone (an insulator), it changes the capacitance between your finger and the electronic material beneath the screen. The smartphone’s technology then interprets that change in capacitance as a command to open an app or to type on the keypad.

Similarly, when your finger touches the elastic fibre, it changes the capacitance between your finger and the EGaIn inside the insulating polymer strands. By moving your finger along the fibre, the capacitance will vary, depending on how many of the strands contain EGaIn at that point in the fibre. This effectively gives you the ability to send different electronic signals depending on which part of the fibre you touch.

“These microscopic fibres may be useful for integrating electronics in new places, including wearable devices,” Dickey said.

The researchers also developed a sensor using two polymer strands, both of which are completely filled with EGaIn. Again, the strands are twisted into a tight spiral. Increasing the number of twists elongates the elastic strands and brings the EGaIn in the two tubes closer together. This changes the capacitance between the two strands.

“We can tell how many times the fibre has been twisted based on the change in capacitance,” Dickey said. “That’s valuable for use in torsion sensors, which measure how many times, and how quickly, something revolves. The advantage of our sensor is that it is built from elastic materials and can therefore be twisted 100 times more — two orders of magnitude — than existing torsion sensors.”

Liquid metal circuits developed for stretchable electronics

Researchers have developed a novel liquid-metal material that is suitable for making flexible and...

Understanding confinement loss in hollow-core fibres

Researchers have gained a better understanding of what makes some hollow-core optical fibres more...

Transferring data with many colours of light

Researchers have developed a new photonic transmitter chip mounted on a circuit board with...