Single-step 3D printing method to create tiny robots

Engineers at the University of California, Los Angeles (UCLA) have developed a new design strategy and 3D printing technique to build robots in a single step, with the results of their research published in the journal Science.

The breakthrough enables the mechanical and electronic systems needed to operate a robot to be manufactured all at once by a new type of 3D printing process for engineered active materials with multiple functions (also known as metamaterials). Once 3D printed, a ‘meta-bot’ will be capable of propulsion, movement sensing and decision-making.

Most robots, no matter their size, are typically built in a series of complex manufacturing steps that integrate the limbs, electronic and active components. The process results in heavier weights, bulkier volumes and reduced force output compared to robots that could be built using this new method.

The key to the all-in-one method is the design and printing of piezoelectric metamaterials — a class of intricate lattice materials that can change shape and move in response to an electric field or create electrical charge as a result of physical forces. The use of active materials that can translate electricity to motions is not new; however, these materials generally have limits in their range of motion and distance of travel. They also need to be connected to gearbox-like transmission systems in order to achieve desired motions.

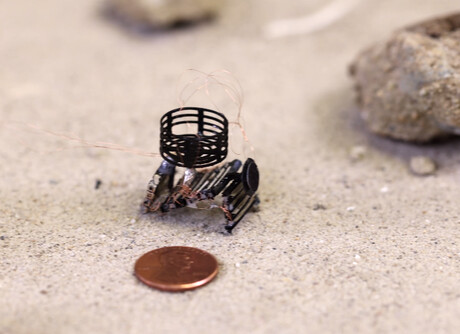

By contrast, the UCLA-developed robotic materials — each the size of a penny — are composed of intricate piezoelectric and structural elements that are designed to bend, flex, twist, rotate, expand or contract at high speeds. The team also presented a methodology to design these robotic materials so users could make their own models and print the materials into a robot directly.

“This allows actuating elements to be arranged precisely throughout the robot for fast, complex and extended movements on various types of terrain,” said lead author Huachen Cui.

“With the two-way piezoelectric effect, the robotic materials can also self-sense their contortions, detect obstacles via echoes and ultrasound emissions, as well as respond to external stimuli through a feedback control loop that determines how the robots move, how fast they move and toward which target they move.”

The printed metamaterials consist of an internal network of sensory, moving and structural elements and can move by themselves following programmed commands. With the internal network of moving and sensing already in place, the only external component needed is a small battery to power the robot.

“We envision that this design and printing methodology of smart robotic materials will help realise a class of autonomous materials that could replace the current complex assembly process for making a robot,” said Associate Professor Xiaoyu (Rayne) Zheng, the study’s principal investigator.

“With complex motions, multiple modes of sensing and programmable decision-making abilities all tightly integrated, it’s similar to a biological system with the nerves, bones and tendons working in tandem to execute controlled motions.”

Using the technique, the team built and demonstrated the fully autonomous operation of three 3D-printed robots — each at the size of a fingernail — with different capabilities. One robot can navigate around S-shaped corners and randomly placed obstacles, another can escape in response to a contact impact, and the third can walk over rough terrain and even make small jumps.

According to Zheng, the methodology could lead to new designs for biomedical robots, such as self-steering endoscopes or tiny swimming robots, which can emit ultrasounds and navigate themselves near blood vessels to deliver drug doses at specific target sites inside the body. The meta-bots can also explore hazardous environments; in a collapsed building, for example, a swarm of such tiny robots armed with integrated sensing parts could quickly access confined spaces, assess threat levels and help rescue efforts by finding people trapped in the rubble.

The advance incorporates 3D printing techniques previously developed by Zheng and Hensleigh while both were researchers at Virginia Tech, which holds the patent. The researchers plan to file an additional patent through the UCLA Technology Development Group for the new methodology developed at UCLA.

Please follow us and share on Twitter and Facebook. You can also subscribe for FREE to our weekly newsletter and bimonthly magazine.

Ricoh chooses u-blox module for long-lasting GNSS performance

The Ricoh Theta X camera incorporates the ZOE-M8B GNSS module from u-blox, allowing users to...

Fast inspection technique for modern semiconductor devices

Researchers developed a novel approach to inspect and measure critical dimensions of...

COM-HPC server-on-modules: limitless freedom for edge servers

Edge server installations have been released from the strict thermal confinements of...