Printed organic transistors for new display technologies

Researchers from The University of Tokyo have successfully printed and demonstrated organic transistors — electronic switches that can operate close to their theoretical speed limits. Their breakthrough has been published in the journal Science Advances.

For around the last 10 years, smartphone and computer screens have been based on a display technology composed of so-called thin film transistors. These are inorganic transistors that require very little power, and they have proven themselves very capable given their widespread adoption. But they have some limits, which researchers have been busy trying to overcome.

“We explore new ways to improve upon thin film transistors, such as new designs or new methods of manufacture,” said Tokyo PhD student Gyo Kitahara. “Organic thin film transistors, for example, have a bright future in LCD screen devices. Compared to the inorganic kind currently used, we expect the organic kind to be useful in low-cost, large-area, lightweight and wearable electronic products, especially by using printing-based production technologies.”

The idea of organic thin film transistors itself is not new, but the ability to print such devices, which would allow for a design revolution, has eluded industry and academics — until now. Kitahara, along with Professor Tatsuo Hasegawa and colleagues, came up with a way to print organic semiconductor films — the basis of these transistors — on a special surface that is highly solution-repellent, or lyophobic. This means ordinarily the surface would repel the materials required to print the structure of the transistor — which would seem counterintuitive, but lyophobic surfaces are responsible for creating transistor structures that are finely tuned for high performance. So how did the researchers overcome their repellent nature?

“We made use of a fluidic property you probably see every time you wash your hands with soap,” Kitahara said. “Soap bubbles can hold a shape by lowering the surface tension of liquid. We presume that the soap-film mechanism should be effective for formation of a thin liquid layer on lyophobic surfaces in spite of the repellent forces. Solid semiconductor films can be formed and grown via the formation of thin liquid layers during the printing processes.”

This is the first time this kind of transistor has been printed and could lead to new curved, flexible and even wearable low-power devices, since high-speed operation only requires low voltages to work. Other researchers now have the opportunity to build on the team’s findings and find ways to scale the method up, which could lead to a convergence between the real world and virtual world in ways we’ve never seen before.

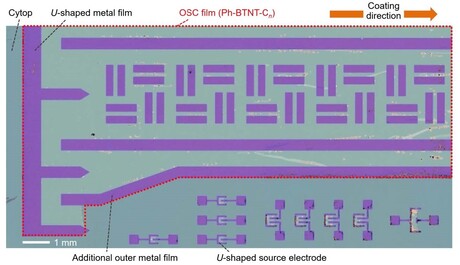

“After having experimented by trial and error, we eventually found that the use of a special U-shaped metal-film pattern seems to be effective for uniform film growth thanks to the way it creates a thin liquid layer on lyophobic surfaces,” Kitahara said. “We anticipated the results beforehand to some extent, but the success of these findings was finally demonstrated and obtained after overcoming several difficulties.”

Please follow us and share on Twitter and Facebook. You can also subscribe for FREE to our weekly newsletter and bimonthly magazine.

Chip-scale optical amplifier enhances data and sensing

Energy-efficient and small enough to fit in a smartphone, an optical amplifier developed at...

Organic transistor 'limitation' improves stability

Researchers have shown that a longstanding organic transistor design limitation actually improves...

OLED circular polarisation is now electrically switchable

Researchers have discovered a way to control left- or right-handed polarised light via charge...