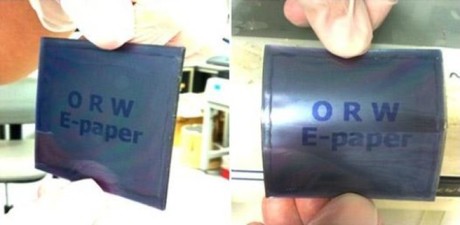

Optically rewritable LCDs are as flexible and thin as paper

Optoelectronic engineers have manufactured a liquid crystal display (LCD) that is paper-thin, flexible, light and tough, not to mention cheap. Described in the journal Applied Physics Letters, the display could apparently cost as little as $5 for a 5″ screen.

The researchers from Donghua University and the Hong Kong University of Science and Technology focused on two key innovations for achieving highly flexible designs, the first of which is the development of optically rewritable LCDs. Like conventional LCDs, the display is structured like a sandwich, with a liquid crystal filling between two plates. Unlike conventional liquid crystals, where electrical connections on the plates create the fields required to switch individual pixels from light to dark, optically rewritable LCDs coat the plates with special molecules that realign in the presence of polarised light and switch the pixels. This removes the need for traditional electrodes, reduces the structure’s bulk and allows more choices in the type and thickness of plates. Consequently, optically rewritable LCDs are less than half a millimetre thick, can be made from flexible plastic and weigh only a few grams.

“It’s only a little thicker than paper,” said study co-author Jiatong Sun from Donghua University.

Optically rewritable LCDs are durable and cheap to manufacture because of their simple structure. Moreover, like an electronic paper screen in an e-book, energy is only required to switch display images or text. Running costs are therefore low, as there is no power required to sustain an image once it is written on the screen.

The second innovation involves the spacers that create the separation of the plastic or glass plates, placed between the glass layers in order to keep the liquid crystal layer uniform. Spacers are used in all LCDs to determine the thickness of the liquid crystal, with a constant thickness necessary for good contrast ratio, response time and viewing angle. However, when plates bend, it forces the liquid crystal away from the impact site and leaves sections of the screen blank; alterations in spacer design are thus critical to prevent liquid crystal in flexible LCDs from moving excessively. Developing a flexible design that overcomes this barrier has proven challenging.

The researchers tried three different spacer designs and found that a mesh-like spacer prevented liquid crystal from flowing when their LCD was bent or hit. This enabled them to create the first flexible optically rewritable LCD.

An additional innovation involved improved colour rendering. The scientists report that until this study, optically rewritable LCDs had only been able to display two colours at a time. Their optically rewritable LCD simultaneously displays the three primary colours — a feat they achieved by placing a special type of liquid crystal behind the LCD, which reflected red, blue and green.

It is believed that the display could be used to host regularly updated sources of information, such as a daily newspaper. But before turning it into a commercial product, Sun wants to improve the resolution of the flexible optically rewritable LCD.

“Now we have three colours, but for full colour we need to make the pixels too small for human eyes to see,” Sun said.

3D semiconductor chip alignment boosts performance

Researchers have developed an ultra-precise method to align 3D semiconductor chips using lasers...

Researchers achieve 8 W output from optical parametric oscillator

Researchers have demonstrated a total output power of 8 W from a high-power mid-infrared cadmium...

"Dualtronic" chip for integrated electronics and photonics

Cornell researchers have developed a dual-sided chip known as a "dualtronic" chip that...