Mid-infrared lasers fabricated on silicon substrates

French researchers have fabricated high-performance mid-infrared laser diodes directly on microelectronics-compatible silicon substrates — a breakthrough that could enable the development of low-cost sensors for real-time, accurate environmental sensing for applications such as air pollution monitoring, food safety analysis and leak detection in pipes. Their work has been described in the journal Optica.

“Most optical chemical sensors are based on the interaction between the molecule of interest and mid-infrared light,” said research team leader Eric Tournié from the University of Montpellier. “Fabricating mid-infrared lasers on microelectronics-compatible silicon can greatly reduce their cost because they can be made using the same high-volume processing techniques used to make the silicon microelectronics that power cell phones and computers.”

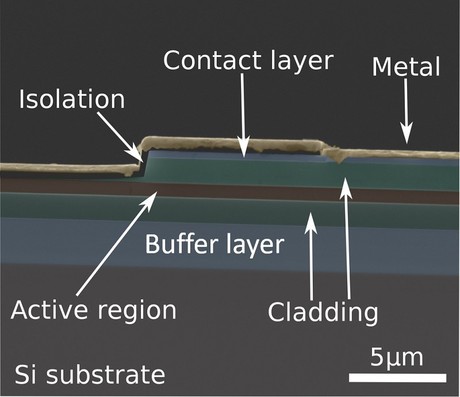

Laser diodes are made of semiconductor materials that convert electricity into light. Mid-infrared light can be created using a type of semiconductor known as III-V. For about a decade, Tournié and his team have been working on depositing III-V semiconductor material on silicon using a method known as epitaxy.

Although the researchers previously demonstrated lasers on silicon substrates, those substrates were not compatible with industry standards for microelectronics fabrication. When using industry-compatible silicon, differences in the material structures of the silicon and the III-V semiconductor cause defects to form.

“A particular defect called an anti-phase boundary is a device killer because it creates short circuits,” Tournié said. “In this new work, we developed an epitaxial approach that prevents these defects from reaching the active part of a device.”

The researchers also improved the process used to fabricate the laser diode from the epitaxial material. As a result, they were able to create an entire laser structure on an industry-compatible silicon substrate with a single run of an epitaxial tool.

The researchers demonstrated the new approach by producing mid-infrared laser diodes that operated in continuous-wave mode and exhibited low optical losses. They now plan to study the lifetime of the new devices and how that lifetime relates to the fabrication and operation mode of the devices.

They say that once their method is fully mature, epitaxy of lasers on large silicon substrates (up to 300 mm across) using silicon microelectronics tools will improve control of the fabrication process. This will, in turn, further reduce laser fabrication costs and enable the design of new devices. The new lasers could also be combined with passive silicon photonics integrated circuits or CMOS technology to create small, low-cost, smart photonic sensors for gas and liquid measurements with high sensitivity.

“The semiconductor material we work with allows fabrication of lasers or photodetectors operating in a broad spectral range, from 1.5 µm (telecom band) to 25 µm (far infrared),” Tournié said. “Our fabrication method can be applied in any field where one needs to integrate III-V semiconductors on silicon platforms. For example, we have already fabricated quantum-cascade lasers emitting at 8 µm by applying this new epitaxial approach.

“At a later stage, these new mid-infrared lasers could be combined with silicon photonics components to create smart, integrated photonic sensors.”

Please follow us and share on Twitter and Facebook. You can also subscribe for FREE to our weekly newsletter and bimonthly magazine.

Novel design for flexible thermoelectric semiconductor

Researchers have identified a new material which could be used as a flexible semiconductor in...

A lighter, smarter magnetoreceptive electronic skin

Researchers have developed an innovative e-skin that facilitates a new level of interaction...

Single transistor used to implement neuromorphic behaviour

Researchers have demonstrated that a single transistor can mimic neural and synaptic behaviours,...