Making transparent conductors — by spreading polymers like butter on toast

Flexible, transparent electrical conductors with record-high performance can now be made by spreading polymers on a clear surface with a tiny blade, like a knife spreading butter on toast.

The technique has already been used to make patterned electrodes for touch sensors and organic solar cells, and with further development could be a tool for manufacturing transparent conductors on a large scale.

Researchers from Stanford University and the Department of Energy’s SLAC National Accelerator Laboratory achieved record-high conductivity by tuning the coating process. “That shows there’s a lot of room for achieving high performance through controlling the assembly and structure of materials at the molecular scale,” said Zhenan Bao, a Stanford professor and member of SIMES, the Stanford Institute for Materials and Energy Sciences at SLAC, who led the study.

Clear conductors for flexible gadgets

Bao’s group developed this ‘solution shearing’ technique in close collaboration with Michael Toney and Stefan Mannsfeld, staff scientists at SLAC’s Stanford Synchrotron Radiation Lightsource (SSRL), whose teams used X-rays to look at the structures and properties of the finished films.

Transparent conductors are used where it’s important to get light in or out of a device, such as in solar cells, electromagnetic shielding, antistatic layers and lighting displays. Today, these conductors are mostly made with indium tin oxide, or ITO. But ITO is expensive to work with, and it isn’t compatible with the flexible displays being developed for a new generation of TV screens, computers and other electronics. In this study, the researchers turned to PEDOT:PSS, a conductive blend of two polymers that turns transparent as it dries. It’s also much cheaper and more flexible than ITO.

Tuning the process

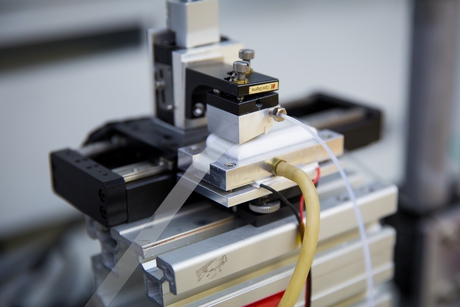

A matchbook-sized silicon blade spread a thin layer of PEDOT:PSS on various surfaces — including glass, silicon and PET, a clear polyester resin used in beverage containers — at speeds up to 6 metres per minute. By varying the speed and adjusting the temperature of this process, the researchers were able to produce see-through films of various thickness and conductivity, and also get the PEDOT and PSS polymers to separate into layers, which increased the film’s conductivity even more. The best films they made beat the existing conductivity record for PEDOT:PSS.

Next they used the method to create working electrodes: first they printed electronic circuit patterns on a glass surface with a chip manufacturing technique called photolithography. Then they spread the polymer mix over the surface with the blade. The conductive polymers stuck to the patterned areas but not to the bare glass, creating circuits where electrical currents can travel. The resulting electrodes were tested and found to work in solar cells and touch sensors.

“Solution shearing is still an experimental technique, but it’s becoming more common as a way to deposit these polymeric materials,” said Sean Andrews, a postdoctoral researcher who carried out the bulk of the experiments with former postdoc Brian Worfolk, now a scientist with Phillips 66. “We’re looking for ways to increase the performance of these films with methods that can be scaled up for industrial manufacturing.” He said the team continues to carry out X-ray studies to find out exactly why spreading the polymers with a blade — which stretches them out along one direction and arranges the molecules in different ways as they dry — makes them more conductive, so they can control and take advantage of the process to make even better transparent conductors.

In earlier studies, the research team used variations of the technique to test better ways to manufacture high-quality semiconductors and solar cells. Their solution shearing apparatus was set up with funding from a SLAC Laboratory Directed Research and Development grant. The research was also supported by the DOE’s Energy Efficiency and Renewable Energy (EERE) BRIDGE program, which aims to significantly lower the cost of solar energy systems; the Stanford Global Climate and Energy Program; Stanford’s Tomkat Center for Sustainable Energy; and the National Science Foundation. Parts of the study were carried out at SSRL, which is a DOE Office of Science User Facility.

A lighter, smarter magnetoreceptive electronic skin

Researchers have developed an innovative e-skin that facilitates a new level of interaction...

Single transistor used to implement neuromorphic behaviour

Researchers have demonstrated that a single transistor can mimic neural and synaptic behaviours,...

Novel fabrication technique for flexible electronics

Researchers have harnessed nature's intrinsic hierarchical fractal structures to improve the...