Light-activated smart plastic a step towards flexible electronics

Researchers at The University of Texas at Austin set out to create a plastic that is hard and rigid in some places and soft and stretchy in others, by using only light and a catalyst to change properties such as hardness and elasticity in molecules of the same type. In doing do, the researchers succeeded in developing a new material that is reportedly 10 times as tough as natural rubber, that could lead to more flexible electronics and robotics. The research findings were published in the journal Science.

Zachariah Page, a corresponding author on the paper, said that the ability to control crystallisation, and therefore the physical properties of the material, with the application of light, could be transformative for wearable electronics or actuators in soft robotics. “This is the first material of its type,” Page said.

Scientists have long sought to mimic the properties of living structures, like skin and muscle, with synthetic materials. In living organisms, structures often combine strength and flexibility with ease. When using a mix of different synthetic materials to mimic these attributes, materials can often fail, come apart and rip at the junctures between different materials. “Oftentimes, when bringing materials together, particularly if they have very different mechanical properties, they want to come apart,” Page said.

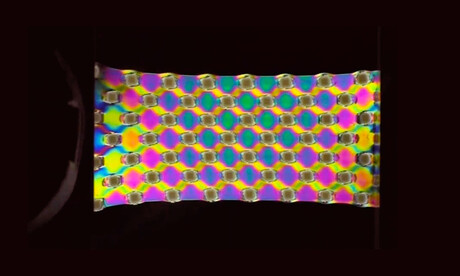

Page and his team of researchers were able to control and change the structure of a plastic-like material, using light to alter how firm or stretchy the material would be. Chemists started with a monomer, a small molecule that binds with others like it to form the building blocks for larger structures called polymers that were similar to the polymer found in the most commonly used plastic. After testing a dozen catalysts, they found one that, when added to their monomer and shown visible light, resulted in a semicrystalline polymer similar to those found in existing synthetic rubber. A harder and more rigid material was formed in the areas the light touched, while the unlit areas remained soft and stretchy. Because the substance is made of one material with different properties, it was stronger and could be stretched farther than most mixed materials.

This reaction takes place at room temperature, the monomer and catalyst are commercially available, and the researchers used blue LEDs as the light source in the experiment. The reaction also takes less than an hour and minimises use of any hazardous waste, which helps to make the process rapid, inexpensive, energy efficient and environmentally benign. The researchers aim to develop more objects with the material, to continue to test its usability.

The material could potentially be used as a flexible foundation to anchor electronic components in medical devices or wearable tech. In robotics, strong and flexible materials are desirable to improve movement and durability.

“We are looking forward to exploring methods of applying this chemistry towards making 3D objects containing both hard and soft components,” said first author Adrian Rylski, a doctoral student at UT Austin.

The research was funded by the National Science Foundation, the US Department of Energy and the Robert A. Welch Foundation.

Single transistor used to implement neuromorphic behaviour

Researchers have demonstrated that a single transistor can mimic neural and synaptic behaviours,...

Novel fabrication technique for flexible electronics

Researchers have harnessed nature's intrinsic hierarchical fractal structures to improve the...

Novel antenna tech developed for 6G communications

Researchers have developed a novel metasurface antenna that can generate and control multiple...