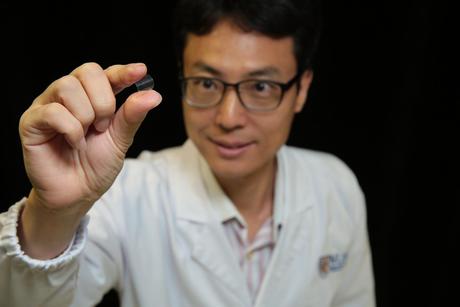

A magnetic memory device on a piece of plastic

Researchers have successfully embedded a powerful magnetic memory chip on a flexible plastic material that is said to demonstrate excellent performance in terms of data storage and processing capabilities, bringing the concept of flexible, wearable electronics closer to reality.

Flexible magnetic memory devices are a fundamental component required for data storage and processing in wearable electronics and biomedical devices, which require functions such as wireless communication, information storage and code processing. Unfortunately, there are still significant challenges in fabricating high-performance memory chips on soft, flexible substrates without sacrificing performance.

To address these challenges, a research team led by the National University of Singapore’s (NUS) Associate Professor Yang Hyunsoo developed a novel technique to implant a high-performance magnetic memory chip on a flexible plastic surface. The work was conducted in collaboration with Yonsei University, Ghent University and A*STAR’s Institute of Materials Research and Engineering, with the results published in the journal Advanced Materials.

The novel device operates on magnetoresistive random access memory (MRAM), which uses a magnesium oxide (MgO)-based magnetic tunnel junction (MTJ) to store data. MRAM outperforms conventional random access memory (RAM) computer chips in many aspects, including the ability to retain data after a power supply is cut off, high processing speed and low power consumption.

The research team first grew the MgO-based MTJ on a silicon surface and then etched away the underlying silicon. Using a transfer printing approach, the team implanted the magnetic memory chip on a flexible plastic surface made of polyethylene terephthalate while controlling the amount of strain caused by placing the memory chip on the plastic surface.

“Our experiments showed that our device’s tunnelling magnetoresistance could reach up to 300% — it’s like a car having extraordinary levels of horsepower,” said Associate Professor Yang. “We have also managed to achieve improved abruptness of switching. With all these enhanced features, the flexible magnetic chip is able to transfer data faster.”

The malleable memory chip is expected to be a critical component for the design and development of flexible and lightweight devices, which have great potential in applications such as automotive, healthcare electronics, industrial motor control and robotics, industrial power and energy management, as well as military and avionics systems. According to Associate Professor Yang, “Flexible electronics will become the norm in the near future, and all new electronic components should be compatible with flexible electronics.”

The researchers are currently conducting experiments to improve the magnetoresistance of the device by fine-tuning the level of strain in its magnetic structure. They are also interested in applying their technique to various other electronic components and working with industry partners to explore further applications of the technology.

“We are the first team to fabricate magnetic memory on a flexible surface, and this significant milestone gives us the impetus to further enhance the performance of flexible memory devices and contribute towards the flexible electronics revolution,” said Associate Professor Yang.

A lighter, smarter magnetoreceptive electronic skin

Researchers have developed an innovative e-skin that facilitates a new level of interaction...

Single transistor used to implement neuromorphic behaviour

Researchers have demonstrated that a single transistor can mimic neural and synaptic behaviours,...

Novel fabrication technique for flexible electronics

Researchers have harnessed nature's intrinsic hierarchical fractal structures to improve the...