Miniaturisation: performance versus power in embedded systems

Learn more about how field programmable gate arrays (FPGAs) will empower the next-generation technology revolution with power-efficient performance in many new applications for every industry.

Miniaturisation is a key feature in most embedded systems today. Everyone wants more computing power in their pockets. Most FPGA-based embedded systems are also following the same trend. Consumers want smaller industrial and professional cameras, medical handhelds, smaller programmable logic controllers (PLCs) and driver assistance modules in cars. Miniaturisation also poses additional challenges — the biggest one can be condensed into a single term, ‘power-efficient performance’. Typically, if a system’s performance goes up, its power consumption does too, which, in turn, increases heat dissipation. And in smaller modules heat dissipation is a headache that designers cope with every day. Cooling a module so that it can operate under a thermally constrained environment often becomes the bottleneck to performance.

This article highlights how field programmable gate arrays (FPGAs) are enabling the next-generation technology revolution by offering power-efficient performance in many new high-volume applications in every industry. Small form-factor cameras can be used for many different things, like running AI algorithms to guide farmers via drone images, providing video analytics in retail chains, counting passengers in transportation and reading licence plates in toll booths. In the medical field, portable ultrasound machines are democratising care delivery in the field. Endoscopes and surgical-assist smart glasses are providing much higher-resolution images to doctors than ever before. Thermal imaging-based surveillance systems designed to protect borders against intruders are also becoming smarter. Generally deployed in remote locations, these systems must operate autonomously while staying hidden.

Even amateur content creators are driving a need for FPGA-based streaming video converters, as they need the option to convert 4K video streams between any format like HDMI, SDI, USB or PCIe.

Industrial automation also benefits from the flexibility of FPGA-based architectures and the longevity of more than 20 years of Microchip FPGAs. Driver assistance systems in automotive keep the driver and passengers safe in cars today.

The FPGA architecture has come a long way. From choosing between performance and power, and only being used as a prototyping platform for expensive ASICs, FPGAs are now considered mainstream, offering highly reliable and cost-optimised architectures, along with flexible and easy-to-use software.

Let’s have a look at various example use-cases where PolarFire FPGAs or PolarFire SoCs, with their hardened RISC-V processor system, are playing a vital role.

Professional drones

Professional drones have strict requirements for flight safety:

- Accurate control and positioning, including collision avoidance.

- Secured communication and control frequencies.

- Predictable flying time.

To be successful in a large drone market, drone manufacturers need to differentiate themselves by providing additional features such as high-resolution imaging and artificial intelligence. The drones often require multiple sensors, pre-processing or fusion of sensor data and transferring that data via a wireless connection, making them complex systems.

The application range is very wide and includes monitoring crop health and growth status in farming, object detection and potentially tracking in policing, military or remote judgement in emergency situations for fire departments or police.

The flight control electronics must be able to handle the motor control and rotor speed, interact with sensors and link up with remote equipment, all in a size-, weight- and power-constrained environment.

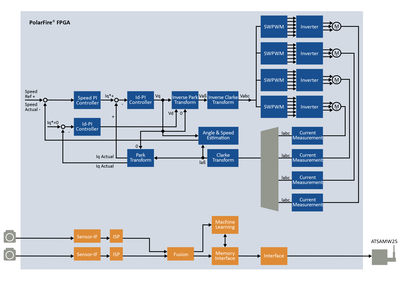

A block diagram for such a system can resemble Figure 1.

Leveraging the flexible FPGA architecture, motors are driven by field-oriented control (FOC) algorithms where control can be time-domain multiplexed because of the performance of the FPGA. Multiple motors are controlled by a common motor control IP, with the exact number of motors depending on the chosen FPGA architecture.

The high accuracy of the FOC allows a constant torque on the motors, resulting in a smoother run with less vibration, less noise generation and most importantly, extending flight time by approximately 10% or more compared to standard motor controllers using simple microcontrollers.

Additional interfaces such as visual light, motion or infrared sensors used to support enhanced features such as machine vision need careful consideration, and historically have required specialised expertise. Microchip’s VectorBlox SDK and matrix processer IP helps novice FPGA developers to deploy complex neural network algorithms in the FPGA fabric. This allows classifications or detections at a very low-power footprint. The neural networks running on this accelerator-IP are designed using standard frameworks like TensorFlow or Caffe.

All results are buffered in local onboard memory and afterwards transferred to an onboard wireless module. This communicates with the operator where the collected data is received for storage and further use. The best-in-class security features of PolarFire devices protect both the transferred data and the drone itself from unauthorised access.

With complex drone architecture needing multiple application domains, motor control, flight control and imaging, using an FPGA provides the benefit of the individual ‘tasks’ running in parallel.

Professional drone systems typically need to operate on a tight power budget of 5 W or less. Using a PolarFire FPGA to manage multiple applications, power consumption of less than 1.5 W for the FPGA, including the operation of the neural network, is expected.

Portable ultrasound

Due to the drive to miniaturise, coupled with power-efficient edge compute resources and enhanced thermal considerations, low-power medical imaging innovation is growing by leaps and bounds. Leading the way are point-of-care diagnostics such as portable ultrasound equipment, consisting of a handheld transducer, reading and sending sonographic data to a standard smartphone. Transmissions can happen with a simple cable or wirelessly. These systems are revolutionising and democratising diagnostic capabilities for emergency medical personal at incident sites, in less developed regions, and helping medical professionals make diagnostic decisions outside traditional hospital environments. The block diagram in Figure 2 shows an example implementation.

Leveraging a PolarFire FPGA in a handheld medical device delivers the lowest total system power, which leads to efficient thermals and keeps the transducer head cool, allowing direct skin contact. These efficiencies extend operation time in a compact package footprint of only 11 x 11 mm2, supporting very small probe enclosures.

Video converters

Another area where flexibility paired with low power consumption and a small physical footprint is essential is the realm of video converters. High-performance professional cameras typically provide a single data interface, limiting post-processing equipment selections that support that specific interface. Having a video converter provide a bridge to several interface standards allows flexibility in selecting post-processing equipment. Performance is not compromised as multi-protocols are supported with numerous multi-gigabit transceivers, and optimised line rates of up to 12.7 Gbps, supporting HDMI, CoaXPress, SDI and Ethernet protocols. The converters’ form factors are compact as heatsinks and fans are no longer required. Video converters built on PolarFire technology are estimated to require less than 2 W of power consumption. Figure 3 provides a video converter design example.

Industrial automation

Two different use cases are used as examples, industrial cameras and programmable logic controllers (PLCs).

Industrial cameras typically require high frame rates, high resolution and a small form factor, which make the thermal design a challenge. Thanks to the optimised package layout, and efficient thermal characteristics, this challenge can be easily tackled. The low static power consumption allows the device to remain cool, enhancing thermal management design considerations. Resolution is not compromised, image data of up to 4K with 60 fps can be easily handled with MIPI CSI-2 receiver-interfaces natively supporting up to 1.5 Gbps/line.

Even though it is physically larger as a complete system, PLCs are similarly space- and power-constrained as cameras.

These rack-based systems are modular, allowing end users to customise their system and offering standard chassis widths. Processing performance is still a must to support industrial Ethernet, human-machine interfaces, motor/driver control and real-time operating systems (RTOS).

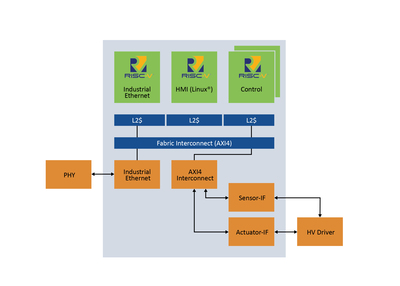

Figure 4 shows a generic block diagram of such a system, mapped to PolarFire SoC, the first FPGA-SoC built on a quad-core RISC-V processor. The PolarFire SoC supports asymmetric multiprocessing (AMP) natively, together with a fixed, fine-granular allocation of cache-ways to individual processors. This native AMP support allows for multi-tasking. As an example, a single processor core can be allocated for an industrial Ethernet protocol stack, while a second core can be running a Linux operating system. The corresponding cache is fixed, and Linux is being separated from other hardware resources. Additionally, the other two available cores can be used to handle the required algorithms for motor control or an inverter.

Again, low power consumption plays an important role keeping the temperature of the electronic components inside the blade modules low, even in challenging thermal environments of 60°C ambient temperature and more.

Industrial automation spans a wide range of applications and requirements. Common amongst industrial products is a need to offer support and availability of devices for 20 years or more. Microchip is fully dedicated to this longevity requirement and offers support with a robust ‘assurance of supply’ program.

Automotive

Many different applications in today’s automotive market require the flexibility of FPGAs, ranging from sensors like LIDAR, imaging radar or cameras to more hidden functionality like highly accurate and closely synchronised driving of electric motors via high-voltage drivers. A strongly emerging application is the use of cameras for collision warning. These cameras allow the detection of dangerous situations with feedback to the driver or also with direct control into the vehicle like automatically activating the brakes. These systems have strong requirements for functional safety, security and low-latency processing, combined with the capability to operate reliably in high-temperature environments caused by engine heat and sunlight.

Figure 5 shows a system setup using the PolarFire MPF050T; safety elements are drawn in yellow, security in green.

The integrated secure non-volatile memory (sNVM) allows the storage of fleet keys to authenticate within the camera module in the vehicle network. The received image frames are processed in streaming mode using the parallel nature of the FPGA and additionally provisioned with additional safety information like frame count and CRC for end-to-end protection of the communication. The streaming processing of the image data avoids the danger of using ‘frozen images’ from memory and allows processing with fixed execution time, directly translating into more time for the system to react. Depending on the exact OEM requirement, the FPGA also provides the required flexibility to support interfacing to various established proprietary serialisers.

Common to all applications, yet not detailed above, are the business drivers for bringing a successful product to market. Looking at how to reduce risk while reaching the client ahead of your competition, and optimising system cost while delivering profits to the bottom line, requires careful consideration of your system architecture and supply partner. The comprehensive Microchip portfolio offers a total system solution partnership. Benefit from key components and reference design solutions to reduce development risk and component counts. Designers can also save time and money as solutions are validated for cross functionality and offer warranties in many cases.

Originally published here.

Spinning, twisted light could power next-generation electronics

Researchers have created an organic semiconductor that forces electrons to move in a spiral...

Improving the way flash memory is made

Researchers are developing the ideal manufacturing process for a type of digital memory known as...

Optical memory unit boosts processing speed

Researchers have developed a fast, versatile volatile photonic memory that could enhance AI,...