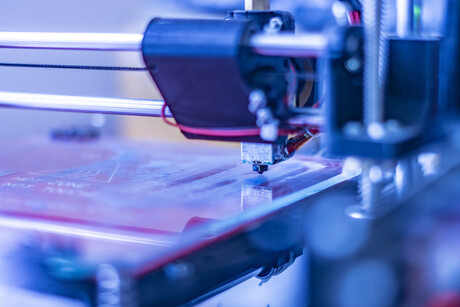

Multi-material 3D printing method for flexible electronics

Scientists from Nanyang Technological University, Singapore (NTU Singapore), Panasonic and the Singapore Centre for 3D Printing (SC3DP) have developed a multi-material printer using multi-wavelength high-power lasers, for quick and easy printing of smart, flexible devices. The multi-material printer works by utilising varying wavelengths of laser, creating thermal and chemical reactions capable of transforming common carbon-based materials (polyimide and graphene oxide) into a new type of porous graphene. The resulting structure printed with this graphene is light and conductive, and can also be printed or coated onto flexible substrates like plastics, glass, gold and fabrics, creating flexible devices.

Electronic devices and components are composed of rigid materials such as metals, silicon and ceramics, but there has been an increasing interest in creating flexible wearable electronics that can be bent, twisted and easily conformed to various surfaces. Associate Professor Murukeshan Vadakke Matham, co-leader of the project, said the project aims to find a way to 3D print new materials like organic polymers and carbon-based materials like graphene, which has properties that allow them to be printed or coated onto flexible substrates like plastics or fabrics, creating flexible and stretchable circuits. “3D printed flexible electronics paves the way for more comfortable and mobile wearable devices as it can be lighter and smaller. We can now create unique structures that were previously impossible with traditional rigid electronics,” Murukeshan said.

The researchers also tested the possibility of integrating 3D printed components into the fabrication of high-performing electronics like pressure sensors and heaters. Co-leader of the project Dr Low Mun Ji, General Manager of Panasonic, said their technology allows the creation of highly porous and conductive graphene-based material for use in different applications. “Compared to traditional graphene manufacturing methods, our method is faster, cheaper and highly compatible with a wide range of materials,” Low said.

The 3D printer offers a high level of flexibility and functionality, with project members saying that the innovation could revolutionise the field of 3D printing and open new possibilities for product design and innovation. The project between NTU and Panasonic to develop the multi-material printer was launched in 2016; over the years, the project team has filed two patents, presented at 11 international conferences and published 11 papers.

For its next steps, Panasonic has set up a new facility for laser-based manufacturing systems at its research hub in Singapore, to enable further trials of concepts using components fabricated by the multi-material printer, as part of “Autonomous Factory” — a Panasonic concept for smart factories of the future. The new facility is to be led by Low and researchers Dr Nicholas Tham and Dr Joel Lim, who were also involved in the joint NTU-Panasonic project.

Terahertz wave control for enhanced wireless technology

Researchers have developed a new patterned spintronic emitter that enables room-temperature...

Upcycling battery waste and CO2 into fuel

Researchers from TU Wien have produced a nanocatalyst based on spent batteries and aluminium foil...

Evaluating the commercial viability of sustainable perovskite LEDs

Researchers have discovered that perovskite LEDs have great long-term commercial potential,...