Researchers develop a fully 3D-printed, flexible OLED display

Researchers at the University of Minnesota Twin Cities have used a customised printer to fully 3D print a flexible organic light-emitting diode (OLED) display. Described in the journal Science Advances, their discovery could result in low-cost OLED displays that could be widely produced using 3D printers by anyone at home, instead of by technicians in expensive microfabrication facilities.

OLED display technology is based on the conversion of electricity into light using an organic material layer. OLEDs function as high-quality digital displays, which can be made flexible and used in both large-scale devices such as television screens and monitors as well as handheld electronics such as smartphones. OLED displays have gained popularity because they are lightweight, power-efficient, thin and flexible, and offer a wide viewing angle and high contrast ratio.

“OLED displays are usually produced in big, expensive, ultraclean fabrication facilities,” said Professor Michael McAlpine, senior author of the study. “We wanted to see if we could basically condense all of that down and print an OLED display on our tabletop 3D printer, which was custom-built and costs about the same as a Tesla Model S.”

The group had previously tried 3D printing OLED displays, but they struggled with the uniformity of the light-emitting layers. Other groups partially printed displays but also relied on spin-coating or thermal evaporation to deposit certain components and create functional devices.

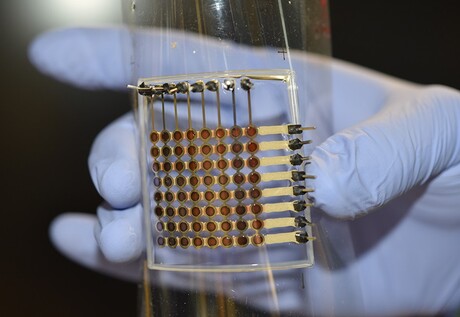

In this latest study, the research team combined two different modes of printing to print the six device layers that resulted in a fully 3D-printed, flexible organic light-emitting diode display. The electrodes, interconnects, insulation and encapsulation were all extrusion printed, while the active layers were spray printed using the same 3D printer at room temperature. The display prototype was about 1.5″ on each side and had 64 pixels. Every pixel worked and displayed light.

“I thought I would get something, but maybe not a fully working display,” said first author Ruitao Su, a University of Minnesota PhD graduate who is now a postdoctoral researcher at MIT. “But then it turns out all the pixels were working and I can display the text I designed. My first reaction was ‘It is real!’”

The 3D-printed display is also flexible and can be packaged in an encapsulating material, Su said, which could make it useful for a wide variety of applications. “The device exhibited a relatively stable emission over the 2000 bending cycles, suggesting that fully 3D-printed OLEDs can potentially be used for important applications in soft electronics and wearable devices,” he revealed.

The researchers said the next steps are to 3D print OLED displays that are higher resolution with improved brightness. According to Prof McAlpine, “It is not hard to imagine that you could translate this to printing all kinds of displays ourselves at home or on the go within just a few years, on a small portable printer.”

Please follow us and share on Twitter and Facebook. You can also subscribe for FREE to our weekly newsletter and bimonthly magazine.

Organic transistor 'limitation' improves stability

Researchers have shown that a longstanding organic transistor design limitation actually improves...

OLED circular polarisation is now electrically switchable

Researchers have discovered a way to control left- or right-handed polarised light via charge...

Nanoscale pixels to advance augmented reality eyewear

Physicists have developed extremely small pixels that can be used in compact AR glasses, using...