Perovskite solar cells pass damp-heat test

In a field dominated by silicon solar cells, the relatively new technology of perovskite solar cells (PSCs) must meet three crucial requirements in order to be successfully commercialised: high power conversion efficiency (PCEs), stability and scalability. In a significant milestone, researchers at King Abdullah University of Science and Technology (KAUST) have now reported a successful PV damp-heat test of PSCs in the journal Science.

The damp-heat test is an accelerated and rigorous environmental aging test aimed at determining the ability of solar panels to withstand prolonged exposure to high humidity penetration and elevated temperatures. The test is run for 1000 hours under a controlled environment of 85% humidity and 85°C. It is meant to replicate multiple years of outdoor exposure and to evaluate factors such as corrosion and delamination.

The harshness of the test is in line with commercialisation requirements of photovoltaic (PV) technology needing to cover 25–30 years of warranty for conventional crystalline-silicon modules. In order to pass the test, the solar cell has to maintain 95% of its initial performance.

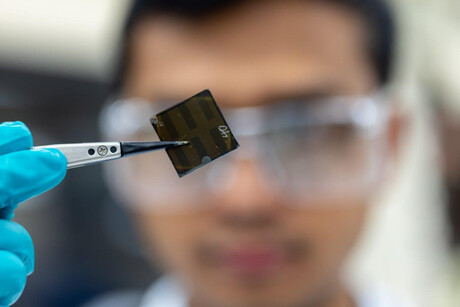

Led by Randi Azmi, a postdoctoral fellow in Stefaan De Wolf’s KAUST Photovoltaics Laboratory, the research had to overcome an enduring weakness in encapsulated PSCs to prevent packaging leakage. This vulnerability of 3D perovskite films is what allows the unwanted infiltration of atmospheric agents and offers limited resilience against heat. The solution found by the KAUST researchers is the engineering and introduction of 2D perovskite passivation layers to simultaneously enhance the power conversion efficiencies and lifetime of PSCs.

As is the case with conventional solar cells, two contacts made of specific types of materials are required for PSCs. One will collect electrons and the other's function is to collect positively charged ‘holes’ — which represent the absence of electrons. But, unlike silicon wafers, perovskites can be coated directly on a glass substrate, using a precursor solution. The solution is made with a solvent that gets crystallised into a solid state. One of the advantages is that precursor materials can be made without the need for expensive facilities and energy-intensive environments of over 1000°C, which is typical for more traditional semiconductors such as silicon.

“It’s a very simple way to make solar cells,” De Wolf said. “Also, while the optoelectronic properties are not unique, they are excellent. They’re on par with very high-quality traditional semiconductors. That’s quite remarkable.”

By altering the composition, it’s also possible to tune the spectral sensitivity across the solar light spectrum from UV up to infrared. This is quite attractive for certain applications.

The remaining challenge, after performance and stability, is scaling. Most solar cell applications are focused on utility-scale sectors as well as rooftop panels.

“The market is silicon-based, and it will be silicon-based for the next 20 years at least,” De Wolf said. “So we are mainly focused on improving the performance of perovskite solar cells in order to advance more efficient ‘tandem’ solutions pairing both traditional silicon and perovskites, where the current findings will aid much in increasing the reliability of such perovskite/silicon tandem solar cells.”

Please follow us and share on Twitter and Facebook. You can also subscribe for FREE to our weekly newsletter and bimonthly magazine.

Battery-like computer memory keeps working in extreme heat

The material transports oxygen ions rather than electrons, creating heat-resistant voltages for...

Producing non-toxic and efficient solar cells

Researchers have developed a new design principle that makes the large-scale production of...

Researchers unveil fast-charging lithium-sulfur battery

Researchers have developed ultrafast-charging lithium-sulfur (Li-S) batteries that could soon...